Products for automobiles

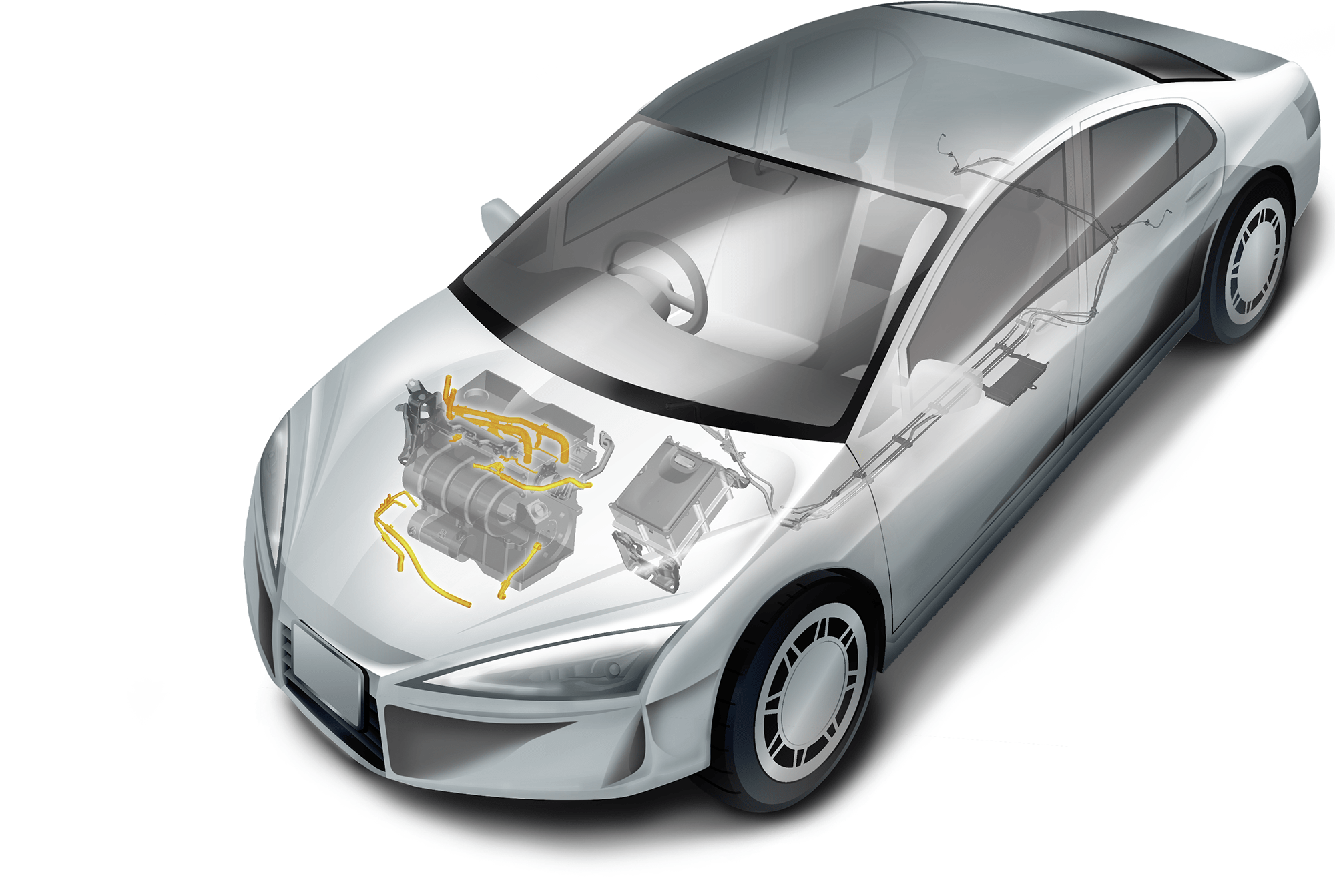

Intake and exhaust system parts

EGR cooler

Heat exchanger cooling EGR gas

Functional part that improves vehicle fuel efficiency by reducing pumping loss and cooling loss.

It is the world’s first high-efficiency EGR cooler for gasoline engines that was adopted to Prius in 2009.

It is compatible with a wide variety of inner fins and constituent materials and boasts the top market share in Japan.

※EGR(Exhaust Gas Recirculation)

=Technology to recirculate part of exhaust gas to the intake side

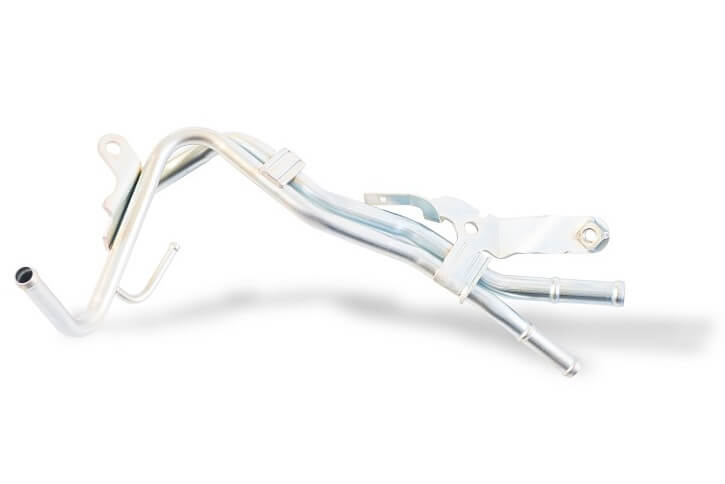

EGR pipe

Pipe to pass EGR gas from the exhaust side to the intake side

Select and adopt the most appropriate stainless material according to the environment of use.

In addition, ensure quality by selecting brazing methods and processing methods according to material type.

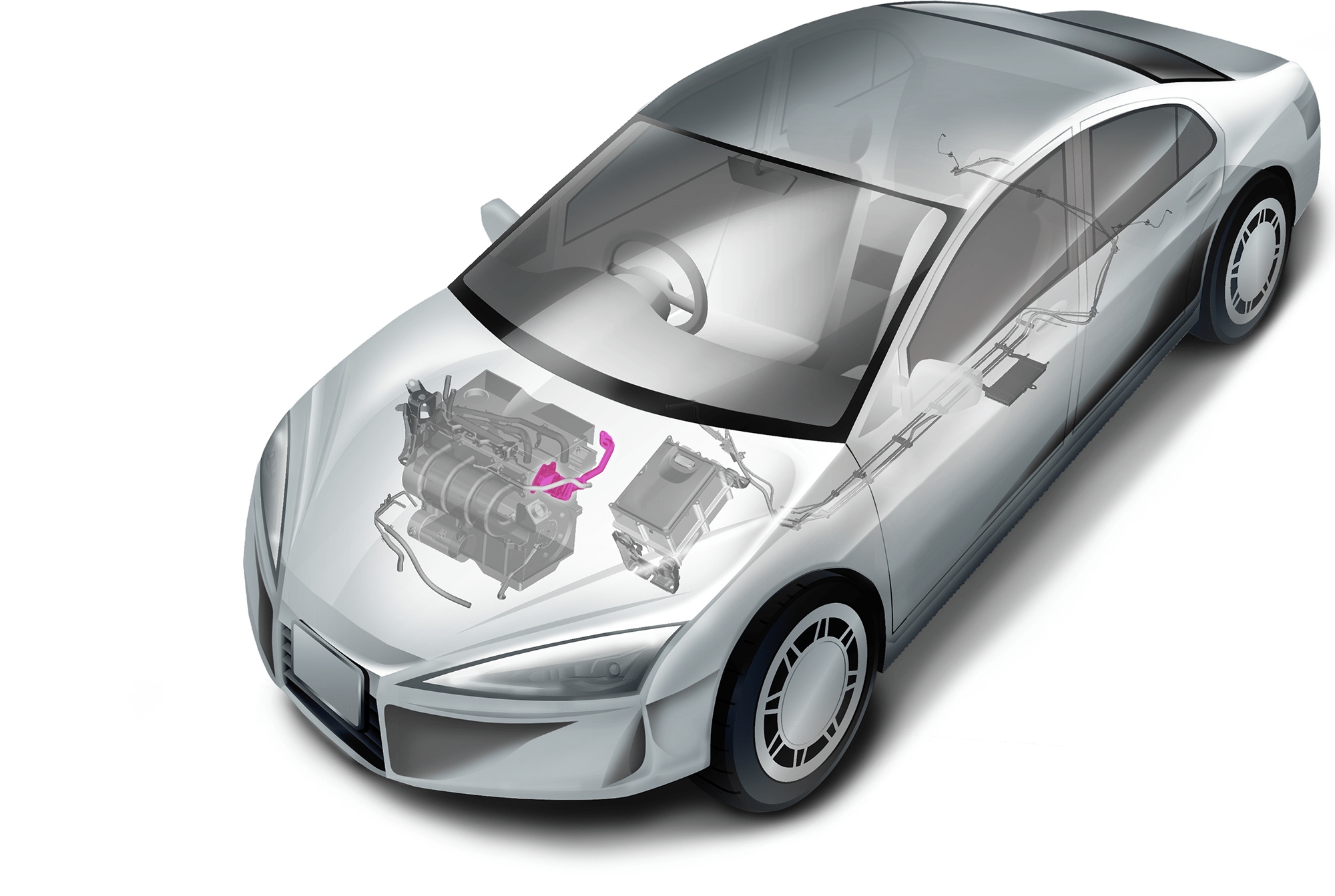

Fuel system parts

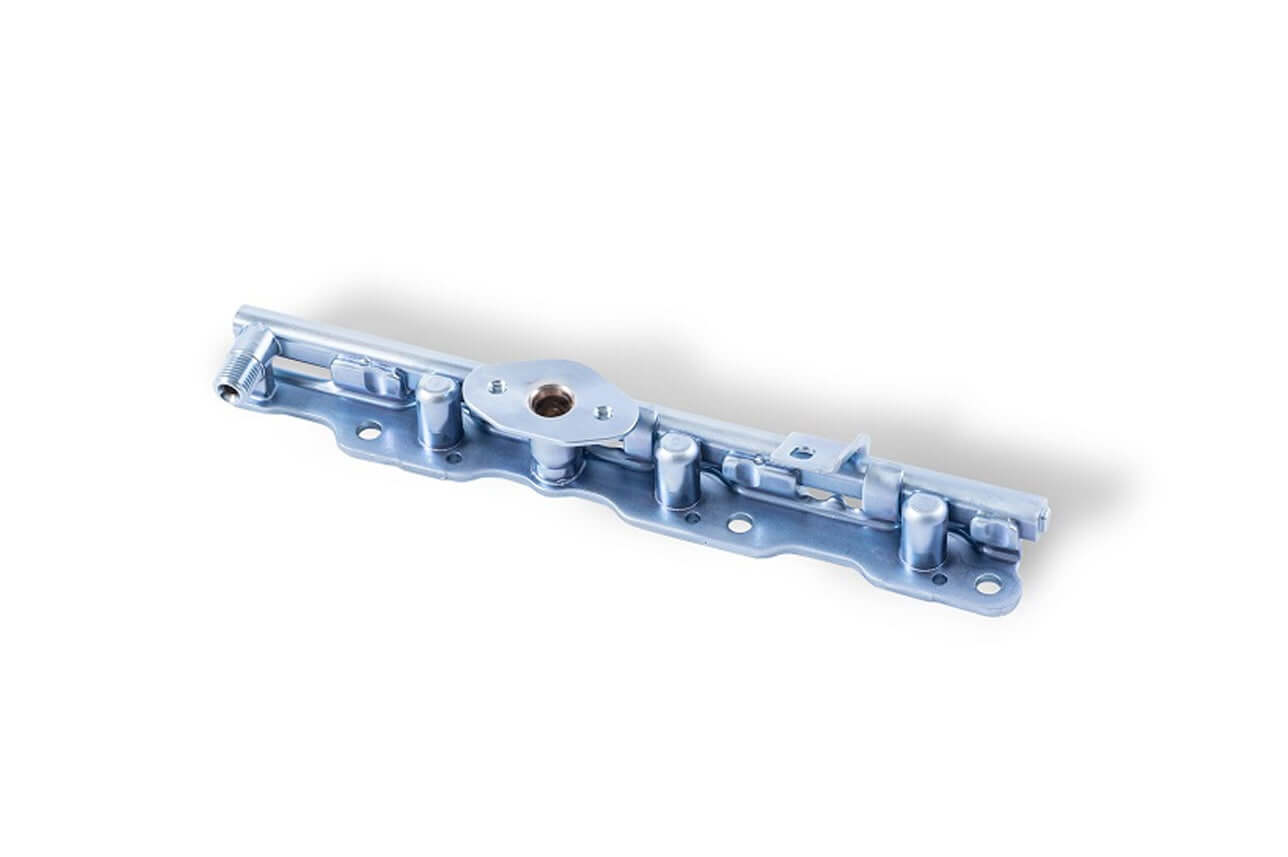

Fuel delivery pipe for high pressure system

Pipe to distribute high-pressure fuel to injectors

It is for direct injection engines and capable of enduring high fuel pressures of 20 MPa or more.

The products we developed for Toyota TNGA series was made of sheet metal, which is the first in the world. Achieving 15% weight reduction and cost reduction in comparison with conventional models.

Utilizing our design, evaluation and joining technology, we accommodate variety of lineups such as sheet metal type, pipe/boss type, and highly corrosion-resistant SUS material. We can offer any of them according to various needs such as use environment, mounting situation or fuel pressure.

Fuel delivery pipe for low pressure system

Pipe to distribute low-pressure fuel to injectors

It is for port injection type engines and suppress fluctuations in fuel pulsation by wall damping mechanisms.

Utilizing our deep drawing press technology, we have realized weight reduction and cost reduction through the integrated structure of injector cup and main portion.

It is applicable to complex situation in engine mounting, and we can offer various design according to customers’ needs.

Fuel delivery pipe with heating room

Pipe to heat and distribute ethanol fuel to injectors

It ensures enough corrosion resistance usable to 100% ethanol fuels in Brazil.

It is the world’s first fuel delivery pipe made of sheet metal that replaced conventional sub-tank. We are the only manufacturer to mass-produce in Japan.

Optimizing fuel flow in heating rooms by CAE analysis technology, we offer products made from presses or forgings suiting to needs such as mounting conditions and required performance.

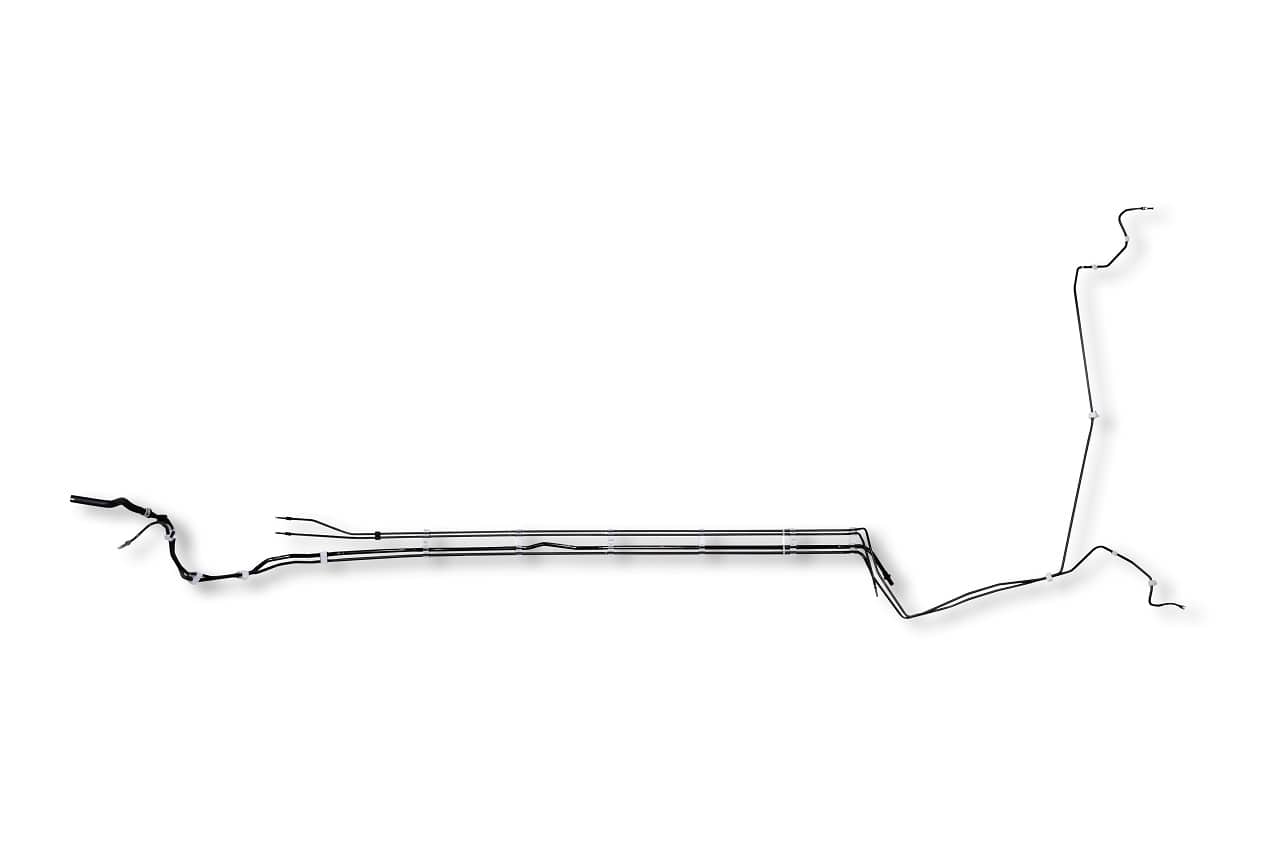

Fuel & Brake tube assy

Consisting of a fuel tube, two brake tubes and a purge tube assembled.

Resin purge tube

Pipe to pass volatile fuel from fuel tank to engine

Pipe to return volatile fuel in fuel tank to engine to prevent it from releasing to atmosphere.

Contributing to weight reduction by 88% and fuel efficiency improvement by using resin instead of conventional iron pipes.

We were the first to use resin for purge pipe in domestic vehicles.

Since the RAV4 (2018), it has been adopted to more than 10 models in and out of Japan as of Jun. 2022.

Fuel cooler

Aluminum heat exchanger with brazing to cool fuel

Cooling risen temperature of fuel due to increase of fuel injection pressure to comply with stricter emission regulations for diesel vehicles.

To prevent thermal damage to fuel system parts.

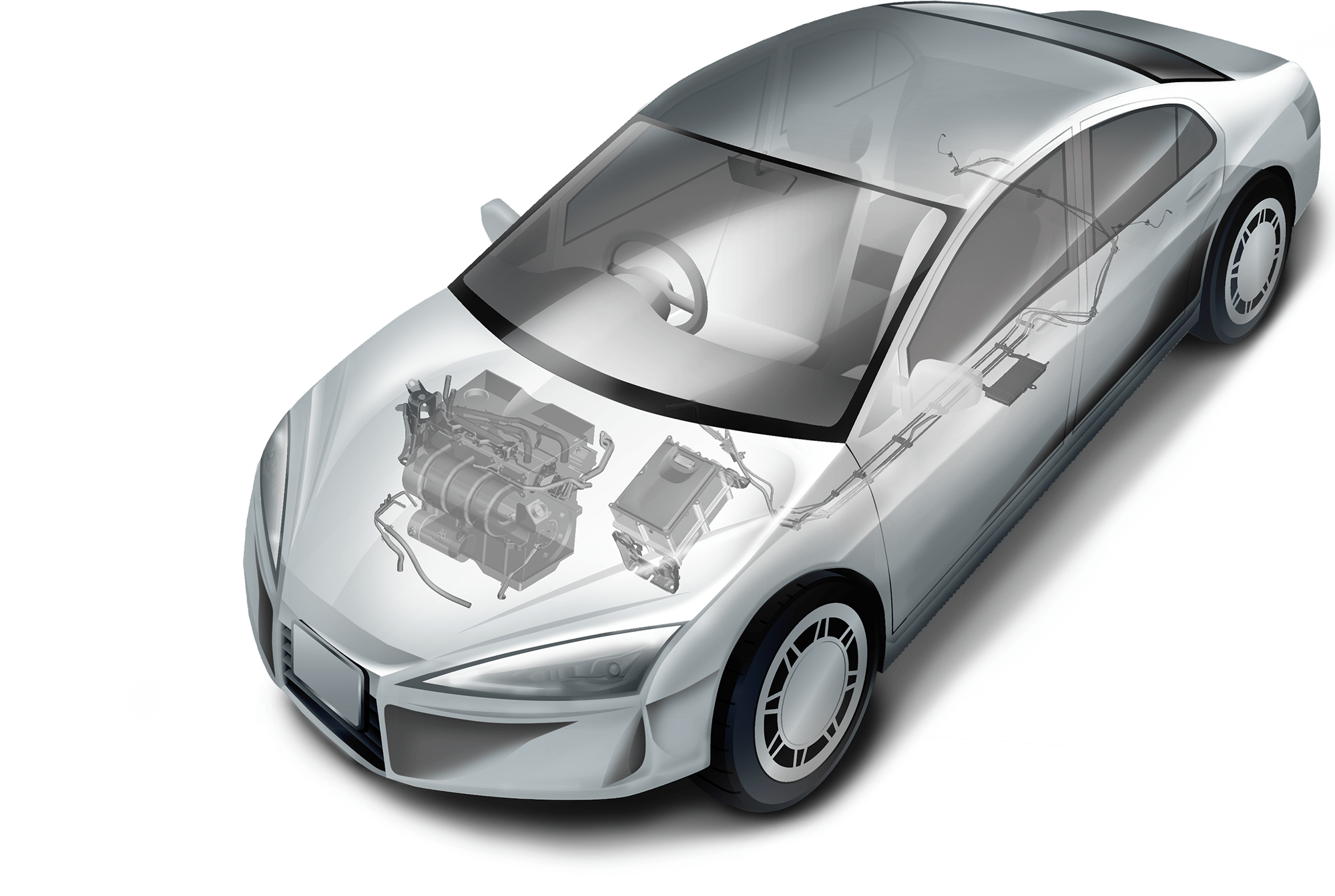

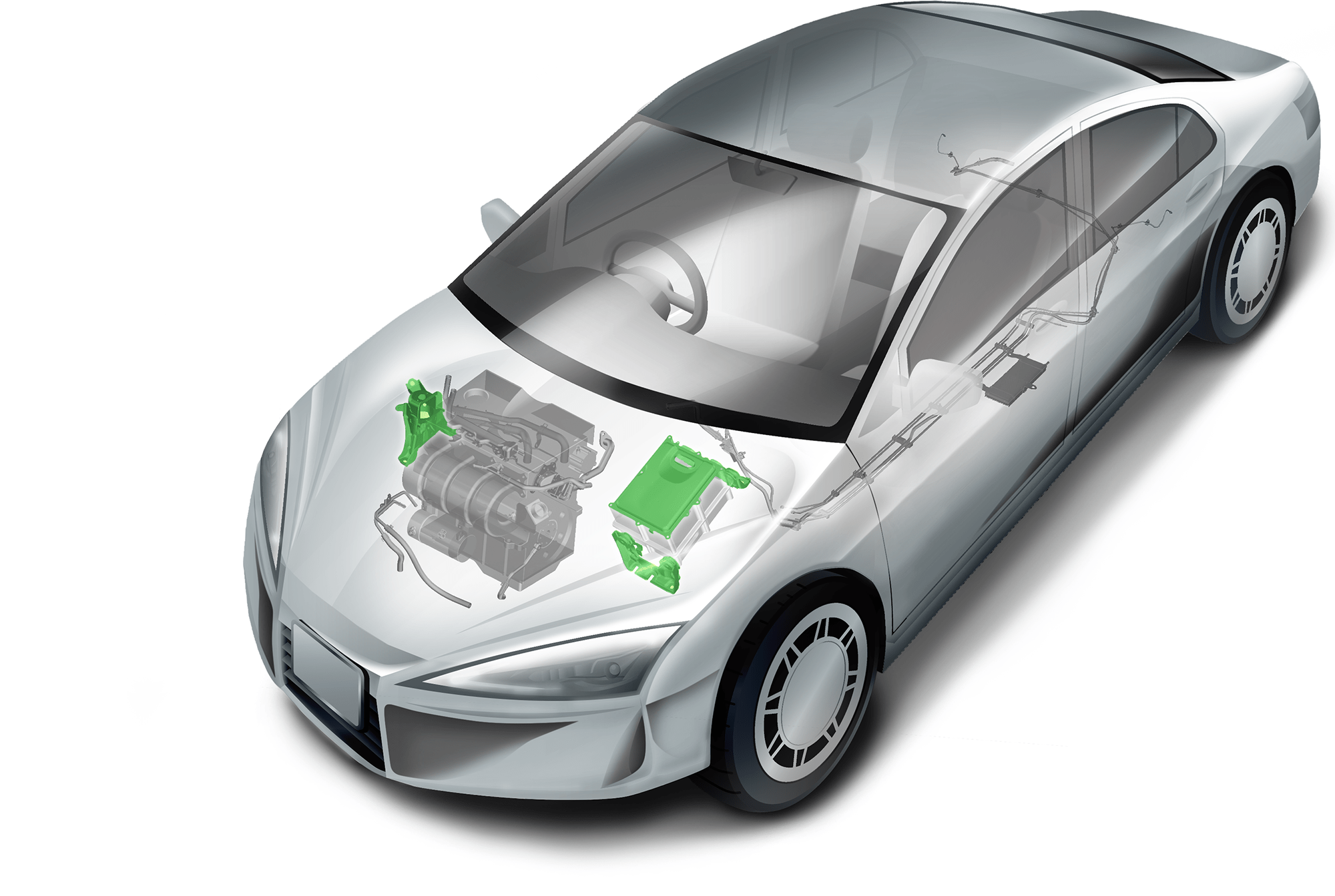

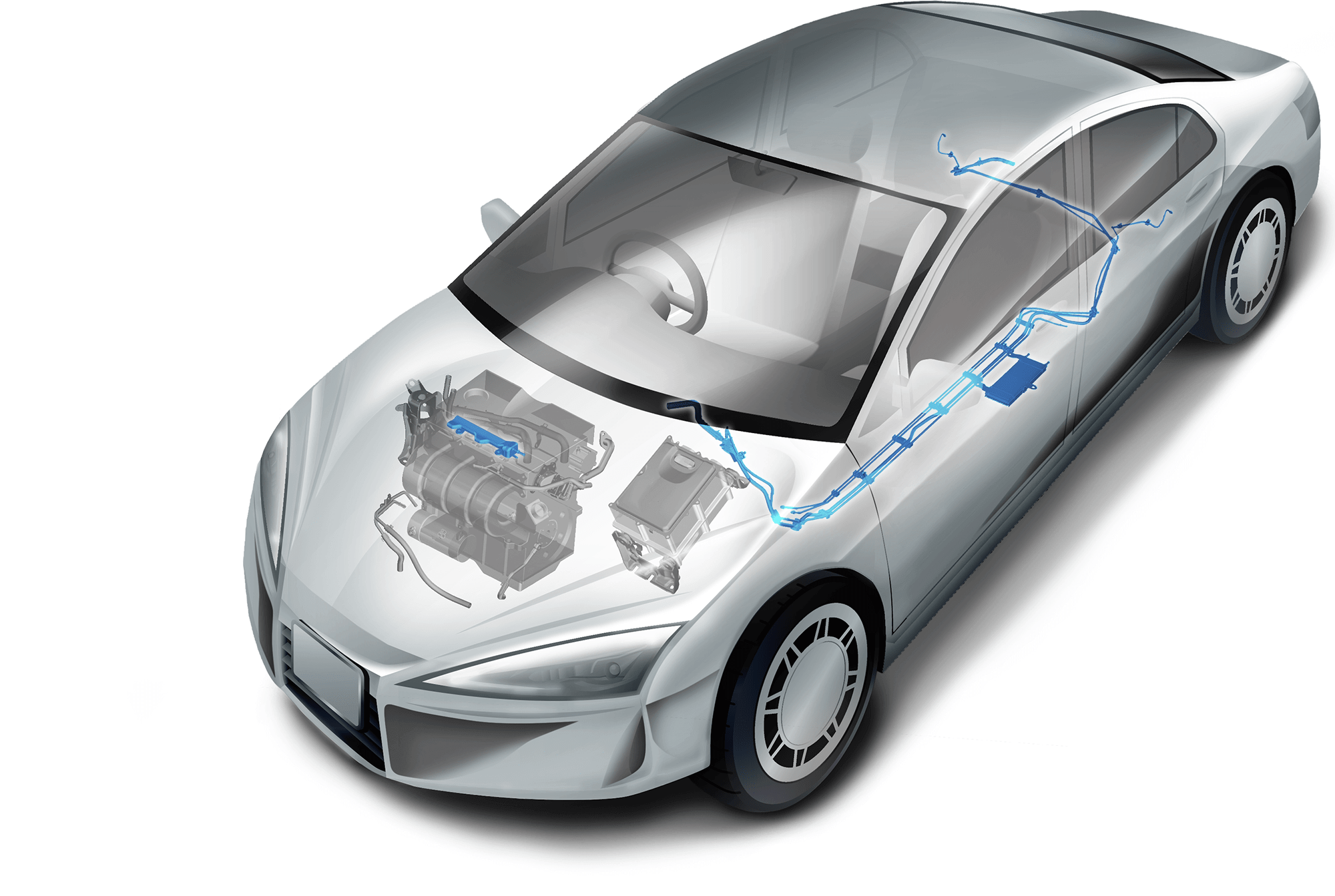

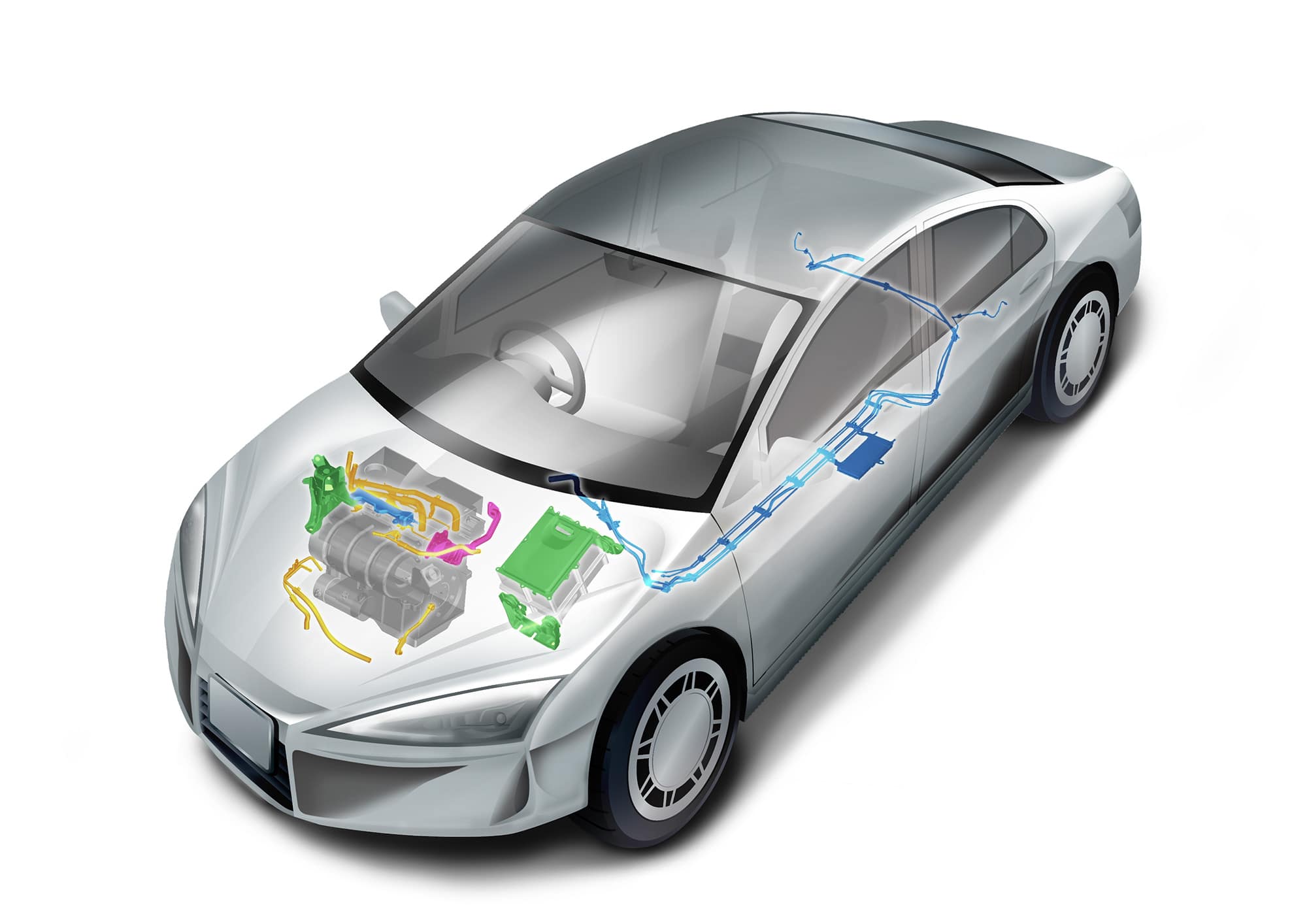

Parts for electric vehicles, others

Upper cover (For inverter)

Protecting electronic components in the PCU (inverter) in the event of a collision.

Iron plate is used to reduce costs and meets strength required to withstand collisions.

In addition, it has high corrosion resistance and design properties by applying a cationic electrodeposition coating.

It was adopted for the first time in 2022. (NOAH, VOXY)

Reducing cost by manufacturing with an integrated production line through pressing to final process.

Inverter bracket for hybrid vehicles

Bracket with vibration reduction performance, impact absorption performance in the event of a collision, and radio noise suppression function.

Holding PCU (inverter), prevents vibrations occurring in engine and transaxle from being transmitted to the PCU, and having a radio noise suppression function.

It has been adopted since Prius in 2015.

We offer optimal shape and complex bracket shapes with optimal processes.

Engine mount bracket

Metal bracket to prevent engine vibration from transmitting to vehicle body.

First product in our history.

It is assembled on vehicle body in combination with vulcanized rubber to support engines.

We have know-how of pressing with complicated shape, welding, painting, and assembly.

We are also able to offer optimal shapes and conduct various evaluation by using analysis technology.

Cooling water/Oil system pipe

Resin pipe in the cooling system

Resin Pipe achieving weight and cost reduction

It has achieved 25% weight reduction and 50% cost reduction compared with conventional ferrous materials.

By adopting PIT for molding process, it is possible to ensure surface property on the inside of pipes and the stability of the wall thickness.

In addition, its material is PPS and it has excellent heat resistance and hydrolysis resistance.

※PIT(Projectile Injection Technology)

=Resin bullet assist molding

Stainless pipe in the cooling system

Stainless steel pipe with high strength, high corrosion resistance, and high heat resistance.

For material of pipes, adopting stainless steel with excellent corrosion resistance.

With our various technique of bending, joining, and end forming for pipes, we are able to accommodate even complicated shapes.

Either welding method or brazing method is available for joining process.

Multiple portions can be joined at once because a whole part is heated in brazing process.

Welding is also available.

Responding flexibly to required product shape and production volume.

Oil cooler tube

Pipe to connect the oil cooler and the transmission

50% weight reduction and 10% cost reduction are achieved by using aluminum pipes in place of conventional iron pipe with surface treatment.

It has excellent corrosion resistance by providing a sacrificial layer on outer surface.

In addition, the necessary strength is ensured by brazing the bracket to the pipe.

Whole part is thrown into brazing furnace and multiple portions can be brazed at once.

We accommodate various design in shape according to customers’ needs including bending shapes.

Motor cooling pipe

Part to pass ATF oil cooled by oil cooler to transaxle

Pipe connecting the transaxle and the motor cooler to cool the oil in the transaxle.

We are able to form pipe end in different shapes according to mating joints.

We also offer different types of surface treatments and bending shapes responding to the used environment.

Oil delivery pipe

Pipe to supply lubrication oil to major sliding parts of engines, such as the camshafts or the connecting rods.

Pipe to supply oil to parts moving with high speed inside the engine.

It injects and supplies oil to the target area and protects the parts inside the engine.