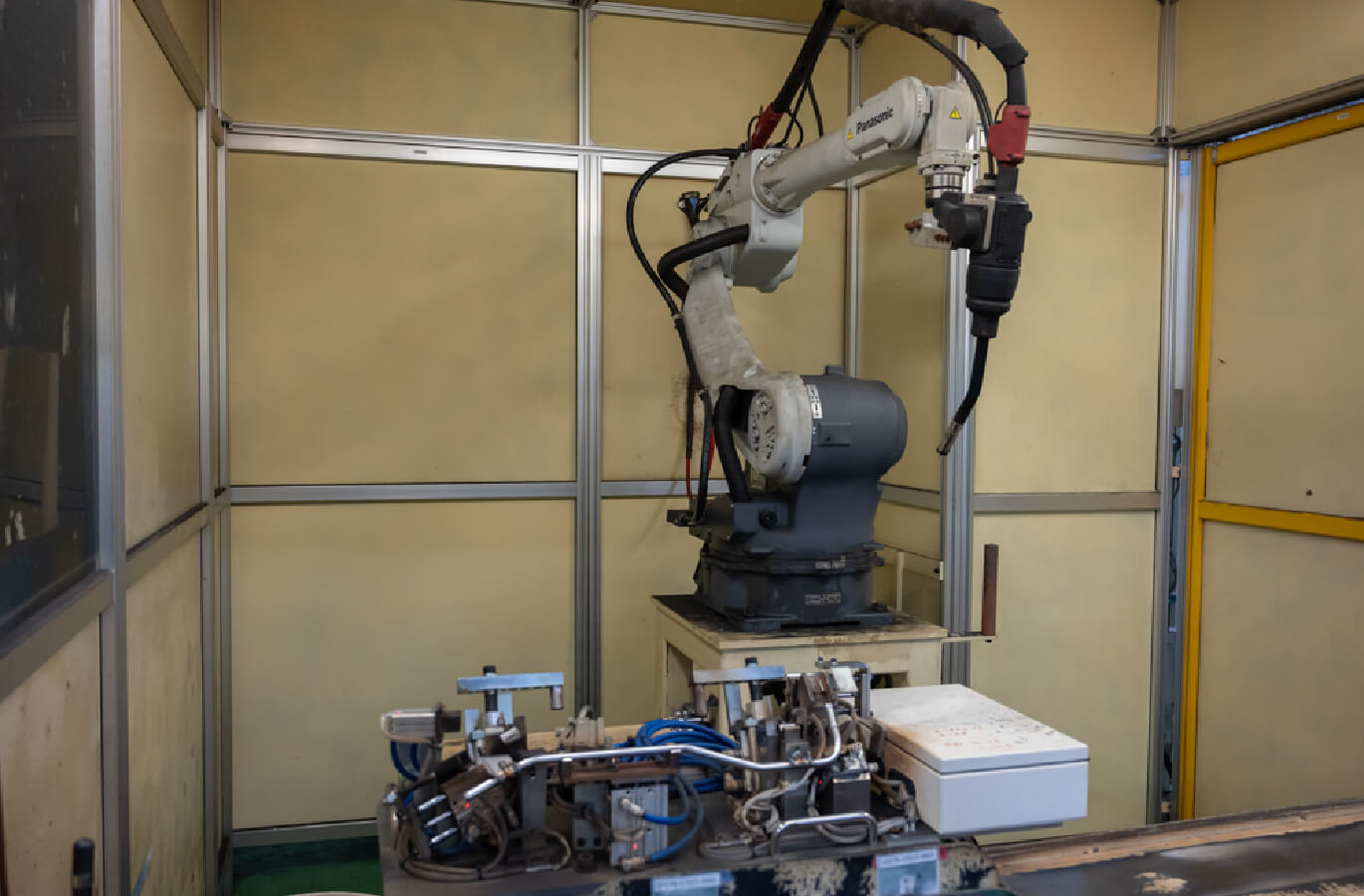

Join by melting base material.

It is used for tack welding to retain product shape before brazing, and for joining engine mounts, etc.

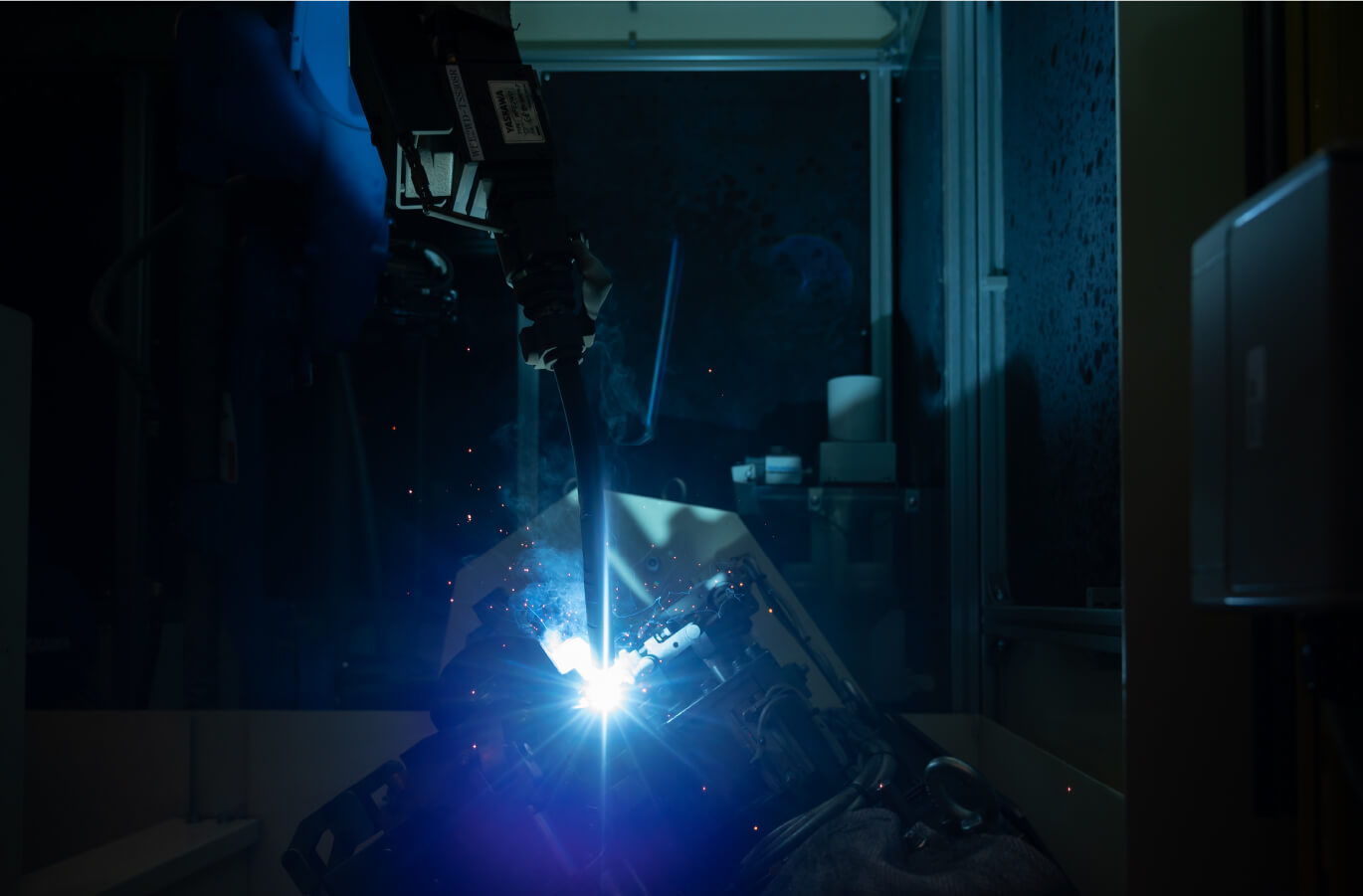

Tig welding

Arc welding with non-consumable electrodes.

This method occurs little spatter and secure stable welding quality.

It is used for tack welding before brazing and joints that require airtightness.

Easier to automate the process.

- Material -

Stainless steel/Iron

- Main products -

- ・EGR cooler (Stainless steel)

- ・EGR pipe (Stainless steel)

- ・High pressure fuel delivery pipe (Steel)

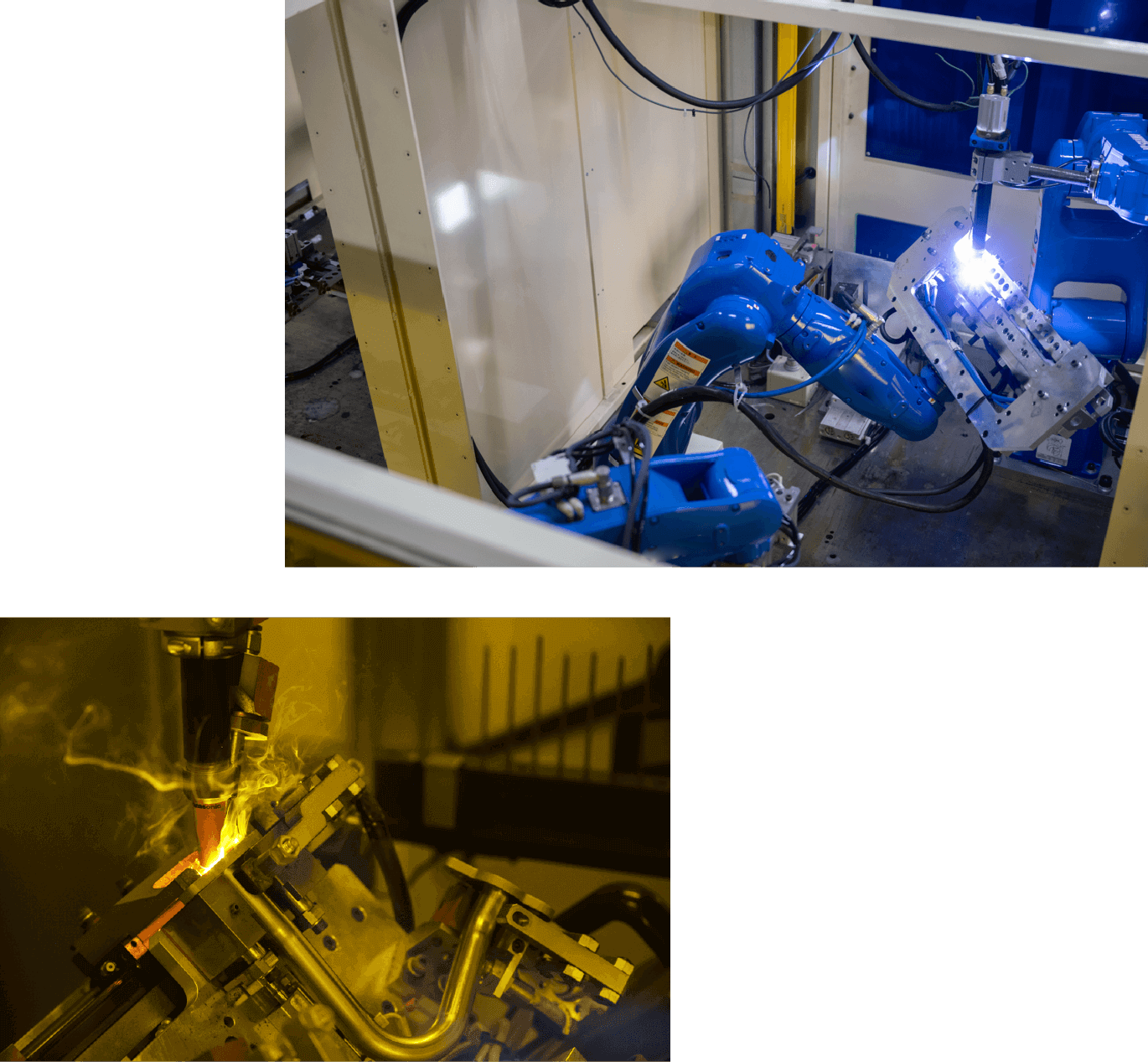

Mig welding

Consumable electrode type arc welding.

It is used at portions where welding strength is required as it can be welded by build-up.

Compared to brazing, one of the advantages is keeping the product shape more stable.

- Material -

Stainless steel

- Main products -

- ・Water pipe (Stainless steel)

CO₂ welding

Consumable electrode type arc welding

It is used at portions where welding strength is required as it can be welded by build-up.

By joining pressed products with CO₂ welding, it is capable of processing products with complex shapes.

- Material -

Iron

- Main products -

- ・Engine mount (Iron)