A joining method that utilizes the difference in the melting points between the base material and the brazing material.

Only brazing material is melted at certain temperature and permeates and diffuses into the bonding surface without melting the base material.

Since a whole product can be heated at once, even complicated shapes can be bonded.

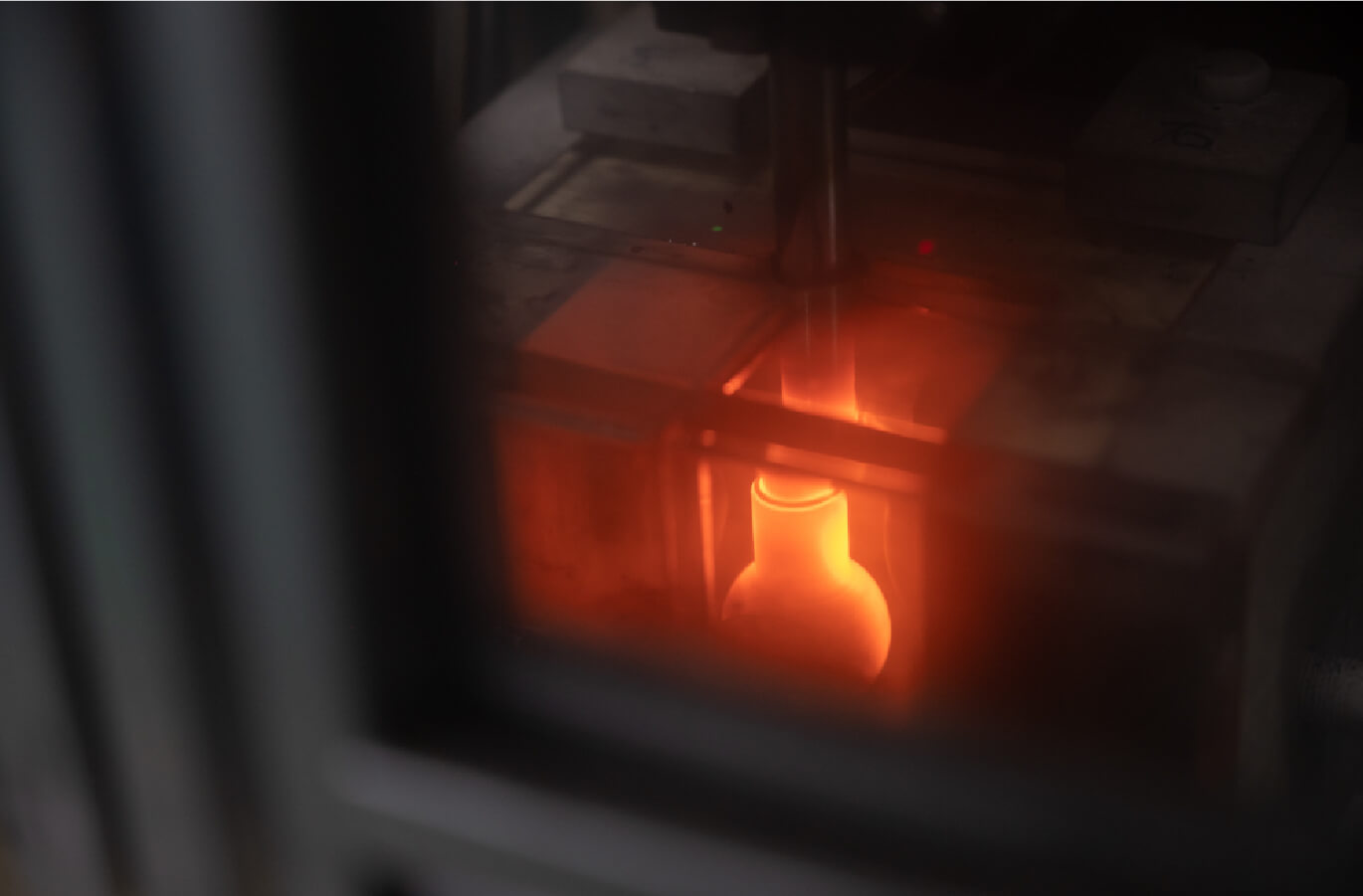

Vacuum furnace brazing

Precise temperature control and cooling speed security is possible.

It can correspond to high-mix, low-volume production to mass production.

- Material -

Base material: Stainless steel/Iron

Brazing material: Nickel alloy/Copper

- Main products -

- ・EGR cooler (Stainless steel)

- ・Water pipe (Stainless steel)

- ・Fuel delivery pipe (Steel)

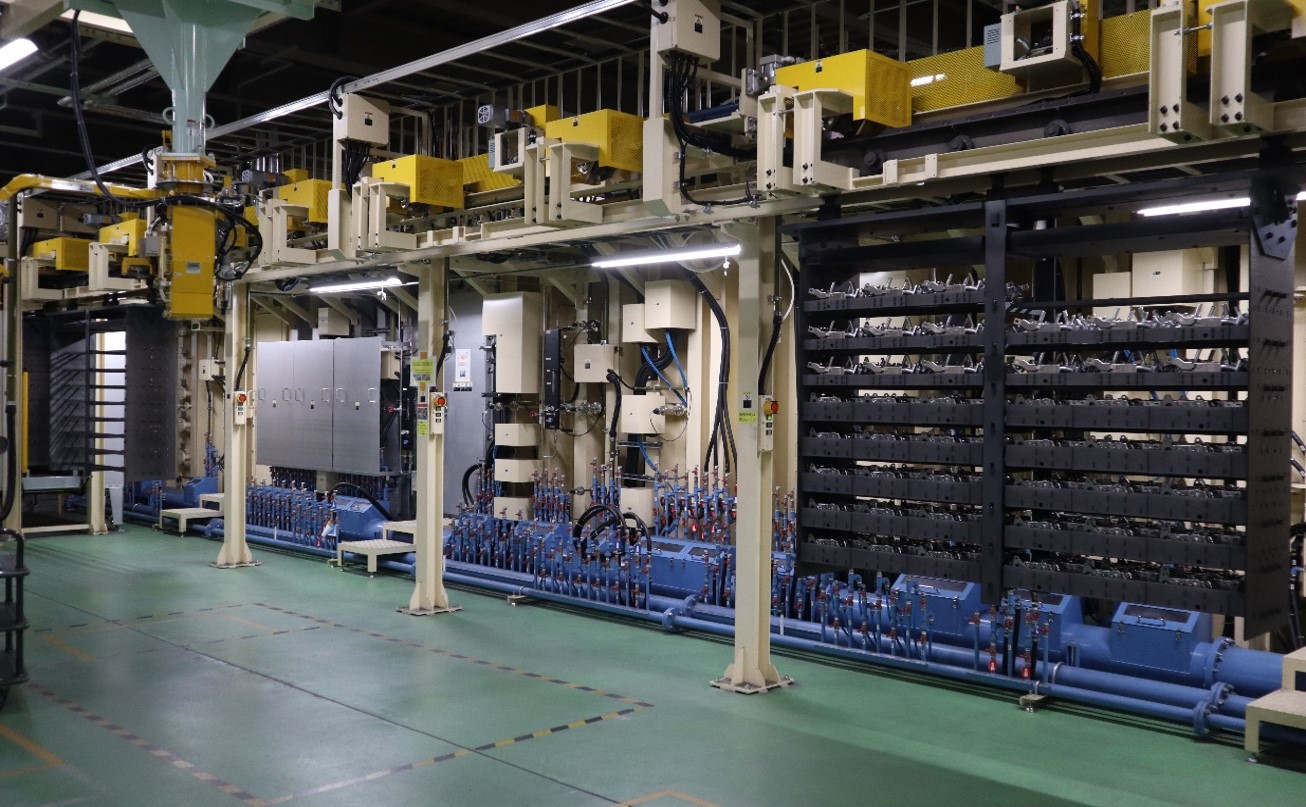

Atmosphere brazing

Many kinds of products can be brazed at once and it enable production with small stock.

It can correspond to high-mix, low-volume production to mass production.

- Material -

Base material: Iron/Aluminum

Brazing material: Copper/Aluminum

- Main products -

- ・Fuel delivery pipes (Steel)

- ・Brake tube (Iron)

- ・Oil cooler tube (Aluminum)

- ・Fuel cooler (Aluminum)

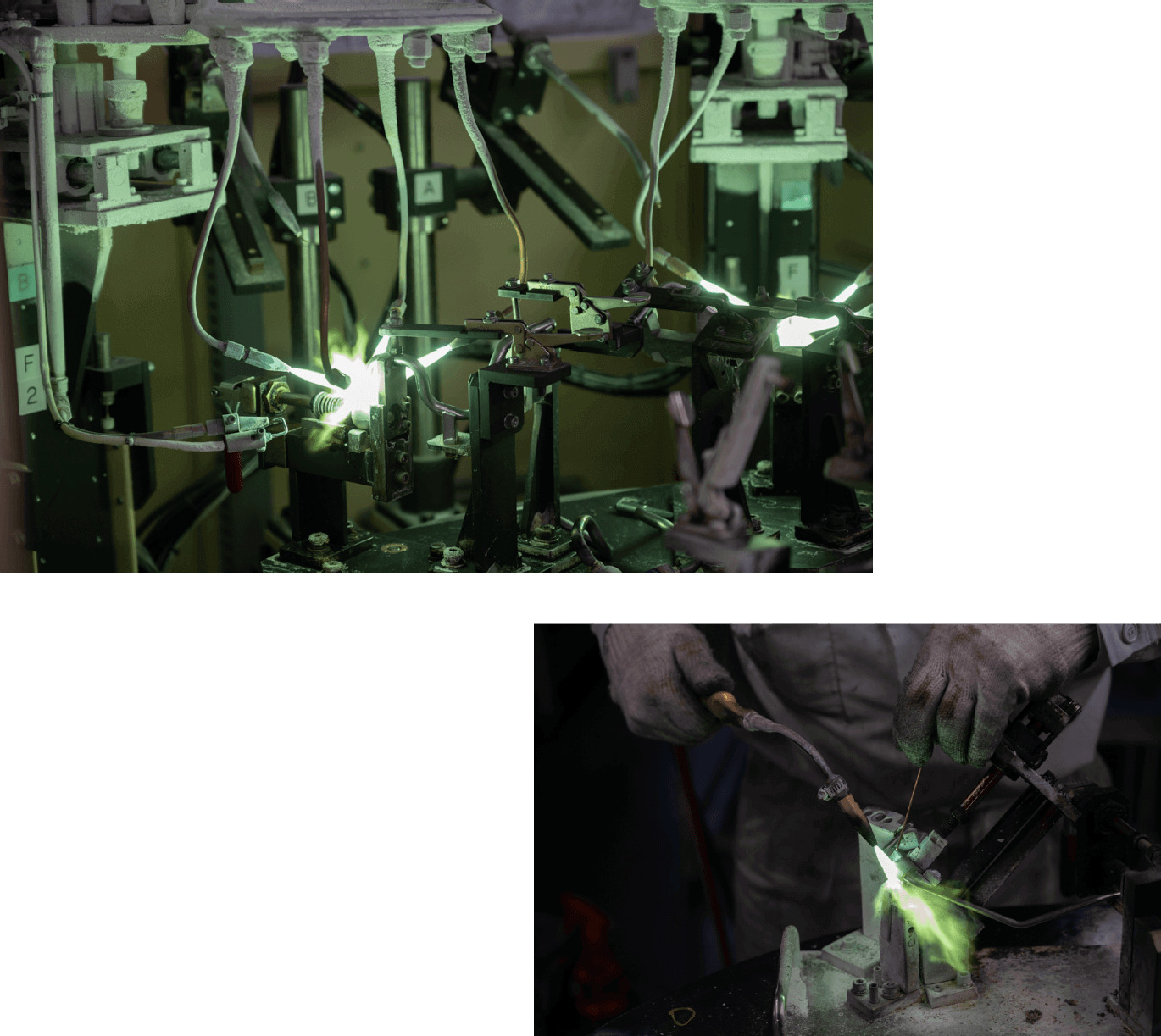

High-frequency induction brazing

Only portions that needs to be brazed is heated with high-frequency.

It enables energy-saving and preventing deformation of products.

It is suitable for small-scale production.

- Material -

Base material: Iron

Brazing material: Copper

- Main products -

- ・Motor cooling pipe (Iron)

Torch brazing

Using torch (Flame) for brazing process and heating only portions that need to be brazed.

It enables energy-saving production and preventing deformation by heat. Also, it can correspond flexibly to low volume production as it can be processed by manual.

- Material -

Base material: Iron

Brazing material: Copper

- Main products -

- ・Oil delivery pipe (Steel)