Interview

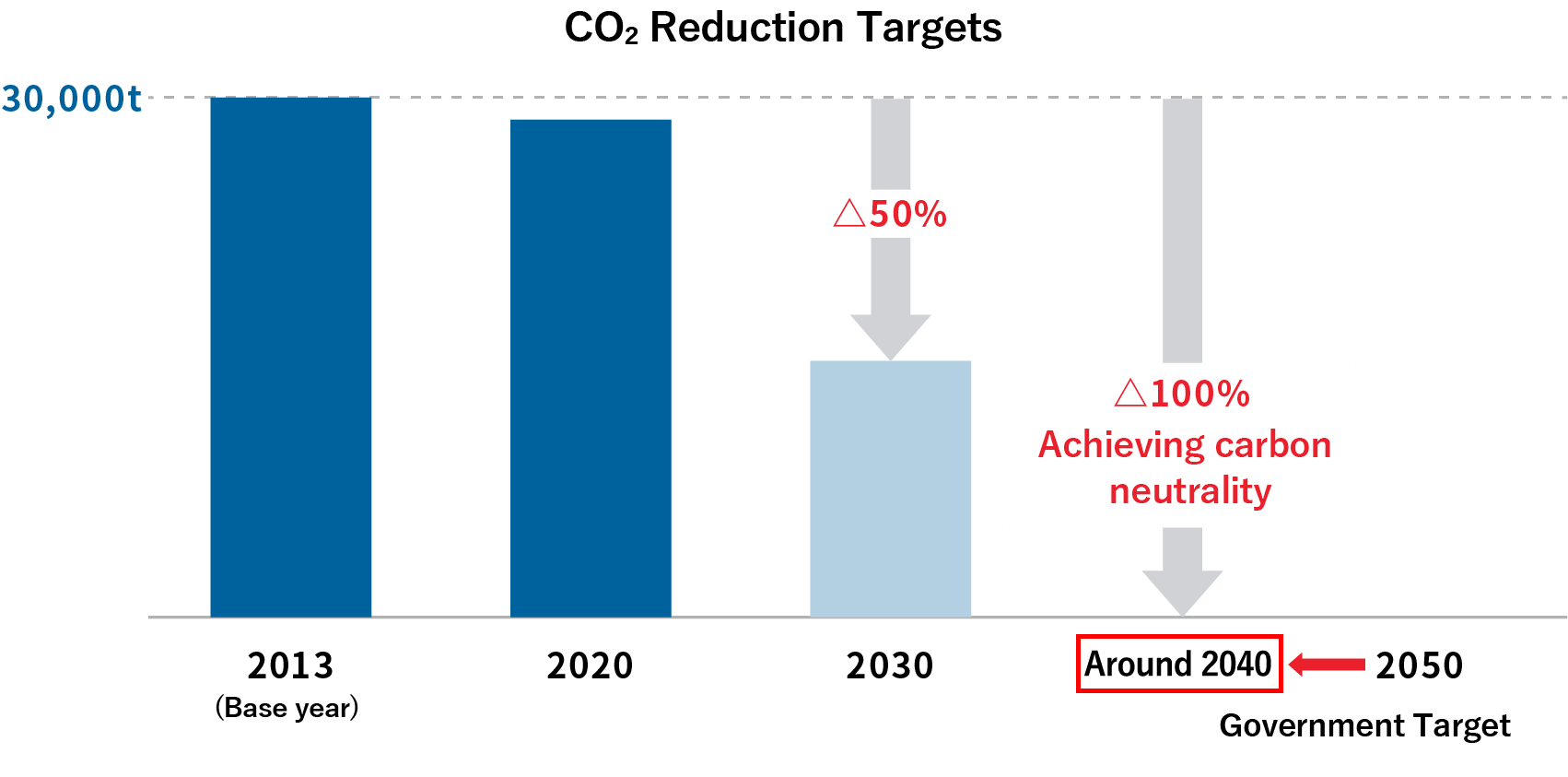

Toward achieving carbon neutrality

by 2040

Electric power infrastructure at the Fukuju Mirai Plant

As part of the development of electric power infrastructure toward realization of a carbon-neutral society, we will introduce a Co-generation system at the Fukuju Mirai Plant (Fukuju-cho, Toyota City), which was completed in March 2022.

The energy efficiency of the electricity we currently purchase is about 40%, and we expect it to be improved up to about 68% by using Co-generation system. Saving more energy by reusing the heat generated during power generation for air-conditioning system in the plant and producing steam for cleaning work.

In addition, we will introduce solar panel power generator to cover a part of electric power for the equipment. We will develop our own power transmission network and promote smart grids(*) that can optimally supply power generated in-house by Co-generation system and solar panels according to the supply and demand situation.

* A system that reuses heat without waste while generating electricity

Activities at manufacturing site

At our manufacturing site as well, we will realize significant reduction in electricity consumption by switching to LED lighting, improving heat insulating property of furnaces, and working to save energy in air conditioners in the plant. In addition, in the manufacturing process, we have come up with many ideas contributing to reduction of CO₂ emissions, such as improving the tube forming process and reducing the amount of industrial waste. We are all working together toward carbon neutral. Our target is to reduce CO₂ emissions by half by 2030 and achieve zero emissions by 2040 through these company-wide efforts.

Toward achieving carbon neutrality across the entire group

Our company emits about 30,000 tons of CO₂ a year.

However, if including our suppliers, it is estimated to be almost twice that amount. We are working with our suppliers to reduce CO₂ emissions in order to achieve carbon neutrality across the entire group, not just thinking about Maruyasu itself.

Through our activities so far, I feel how important continued steady energy-saving activities are, such as each employee searching for ideas and repeatedly verifying them.

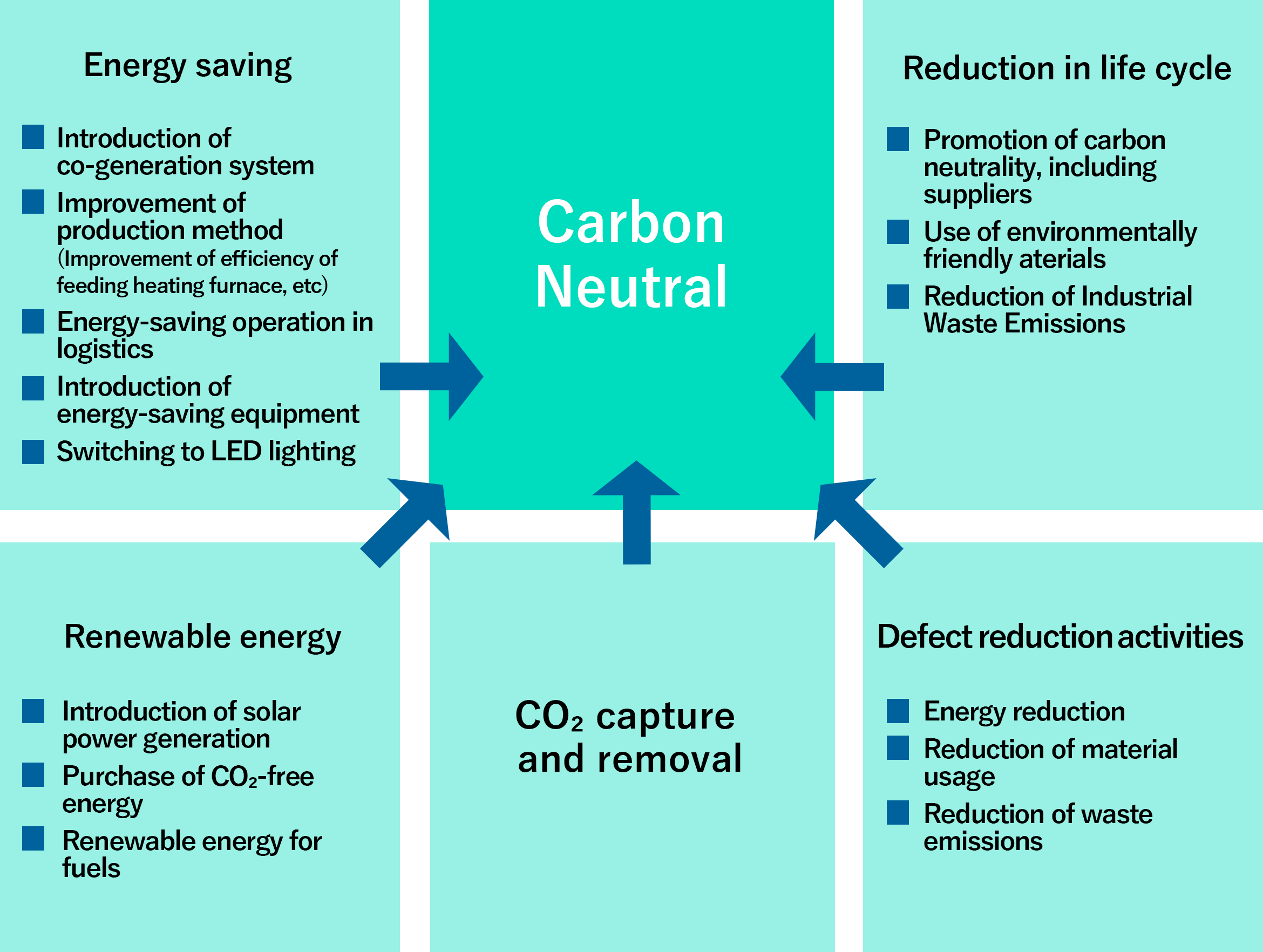

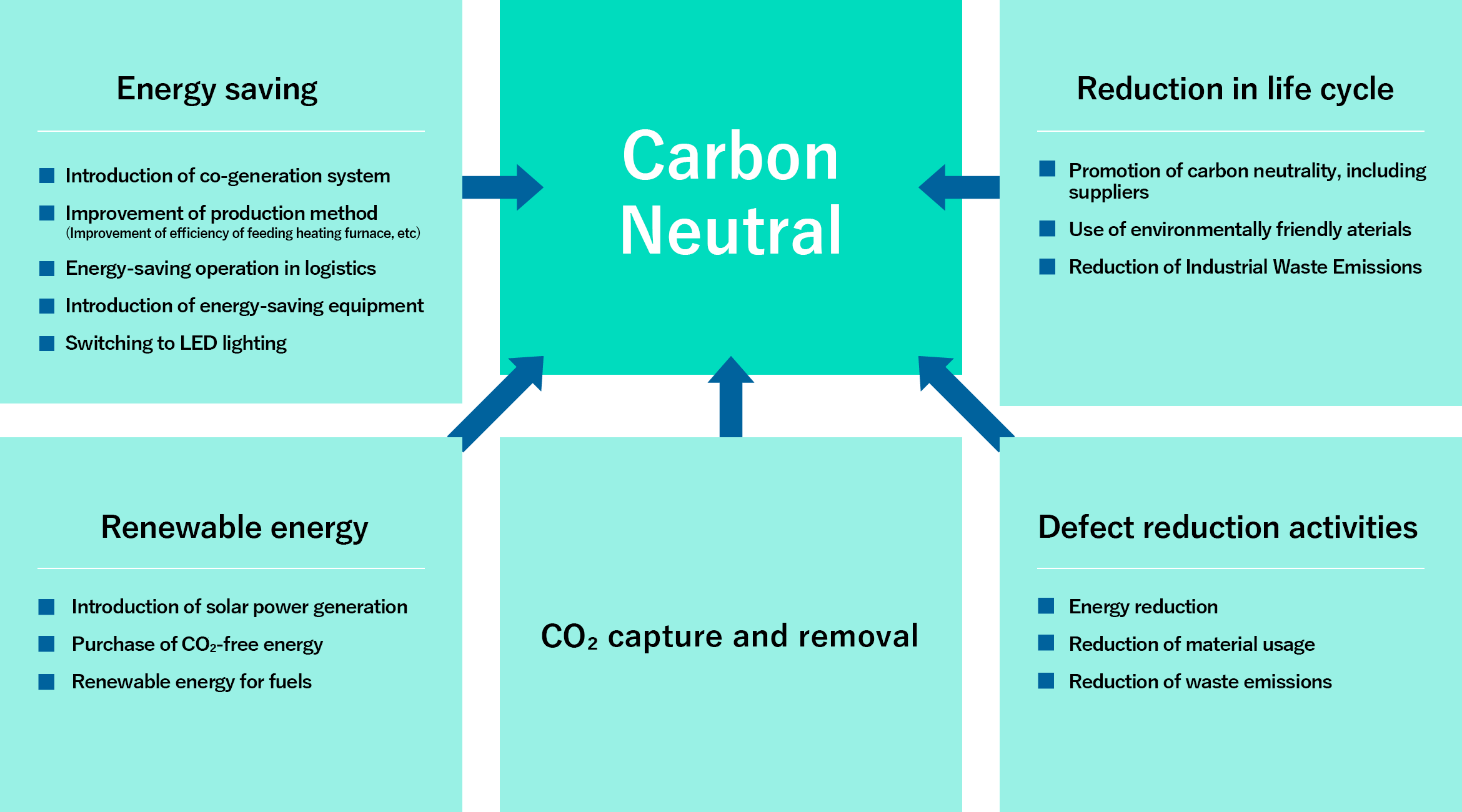

Our 5 missions to achieve zero CO₂ emissions

We actively work on reduction of CO₂ in all corporate activities, including product manufacturing and transportation processes.

Not just promoting energy-saving at manufacturing site, we will promote efforts toward carbon neutrality, such as reducing CO₂ emissions across entire group, restructuring the global production system, and reducing logistics itself.

Contribution to carbon neutrality through

environmental preservation activities

We work on environment-related activities based on our belief that all of them will lead to CO₂ reduction.

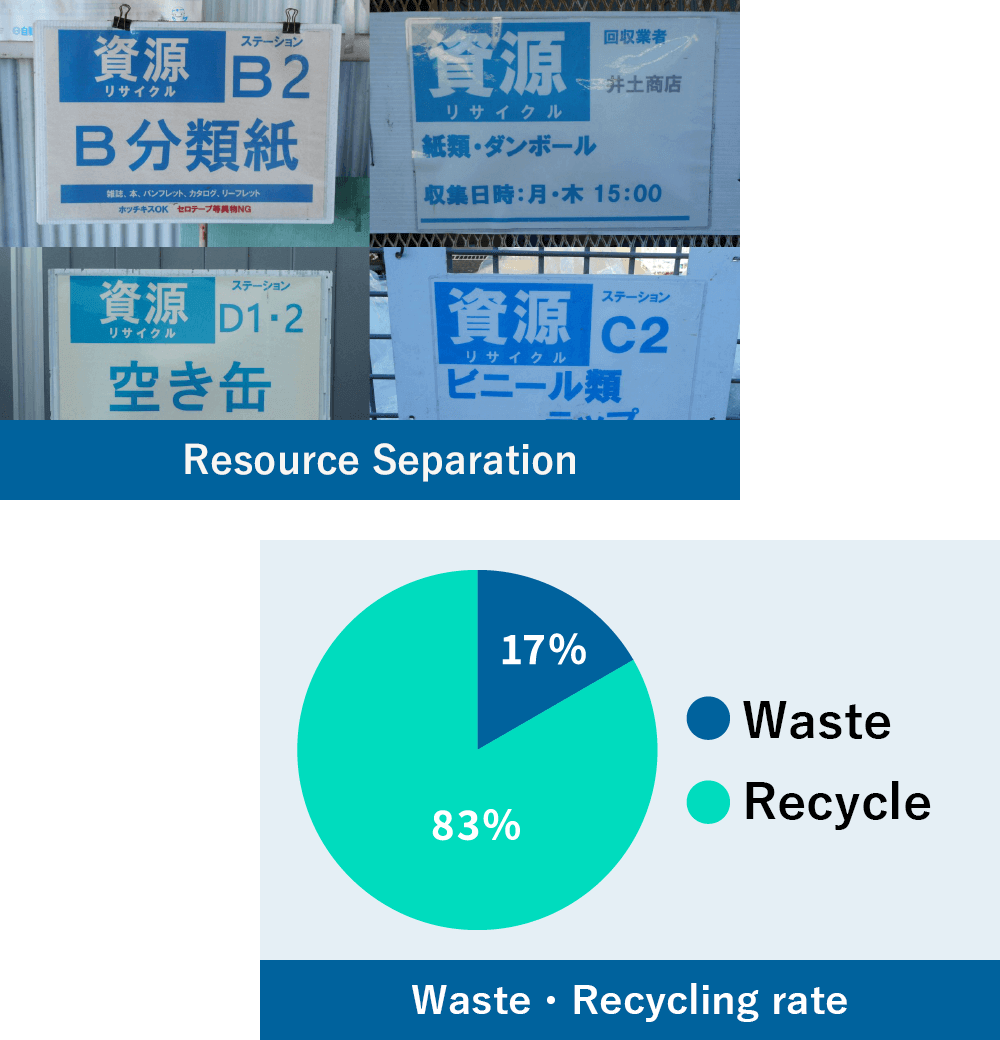

Resource circulation

We separate and collect materials that can be recycled to resources and reduce waste.

83% of wasted material is recycled.

We will reduce CO₂ emissions in waste disposal.

Water environment conservation

We work on reduction of water consumption and observe the first-rate strict water quality standards in Japan by properly treating and managing wastewater from the plant.

Chemicals

We thoroughly manage chemical substance used in our plant and our products and strive to minimize global warming, environmental pollution, and influences on organisms.

Biodiversity

We observe the top-level strict water quality standards in Japan for the conservation of biodiversity and contribute to preservation of aquatic organisms (such as short-necked clams) in the Yahagi River and Mikawa Bay.

Environment-contributing Products

We are working on the development of environment-contributing products, with the goal of developing two or more products with an environmental index* of 1.2 or higher each year.

(* Based on the Product Environmental Indicator Guidelines of the Japan Auto Parts Industries Association)