We have a wide variety of technologies such as press technology forming metal,

“plastic processing” used for tube processing or others, and “injection molding”

and “extrusion molding” , which is molding resin into designed shapes by heating and melting it.

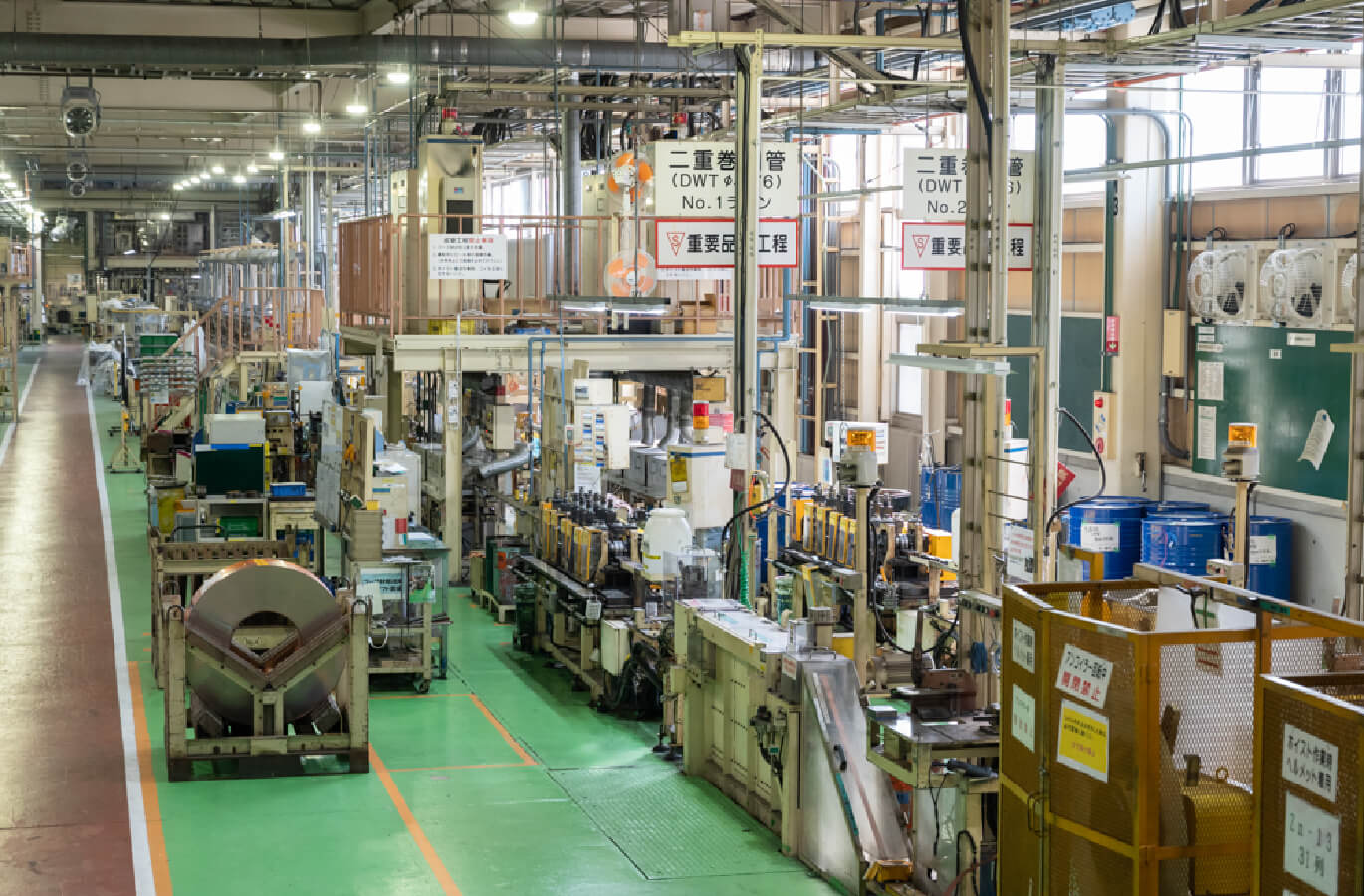

Roll-forming

Technology to form a strip of thin plate into the desired shape with multiple rolls.

We produce 2 types of tube,Single-walled tube with the process of rolling strip-shaped thin plate into a tubular shape and welding both ends at the top.

Double-walled tube having higher pressure resisting strength with the process of rolling strip-shaped thin plate in double into a tubular shape and brazing.

- Material -

Stainless steel/Iron

- Main products -

- ・Fuel pipe (Iron)

- ・Brake pipe (Iron)

- ・Cooling water pipe (Stainless steel)

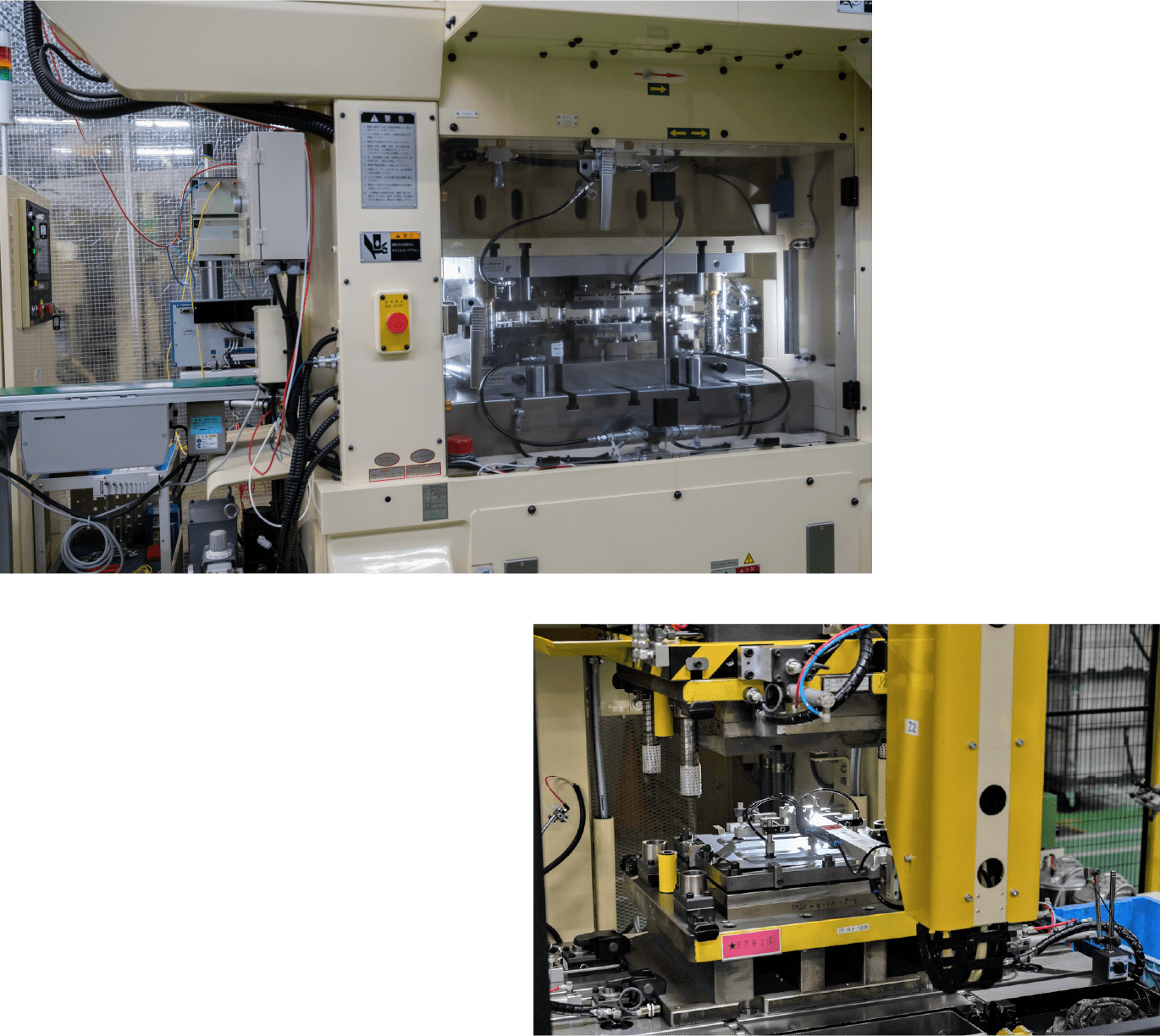

Press

Technology that forms steel plate with press dies and has high productivity.

It is also used for products require design.

- Material -

Stainless steel/Iron/Aluminum

- Main products -

- ・Upper cover (Iron)

- ・EGR cooler components (Stainless steel)

- ・Engine mount (Iron)

- ・Oil cooler tube bracket (Aluminum)

Pipe end forming technology

Process to make shapes at pipe ends for joining and sealing.

It has high productivity and can process high-precision end shapes.

- Material -

Stainless steel/Iron/Aluminum

- Main products -

- ・Fuel pipe (Iron)

- ・Brake pipe (Iron)

- ・EGR cooler (Stainless steel)

- ・Fuel cooler (Aluminum)

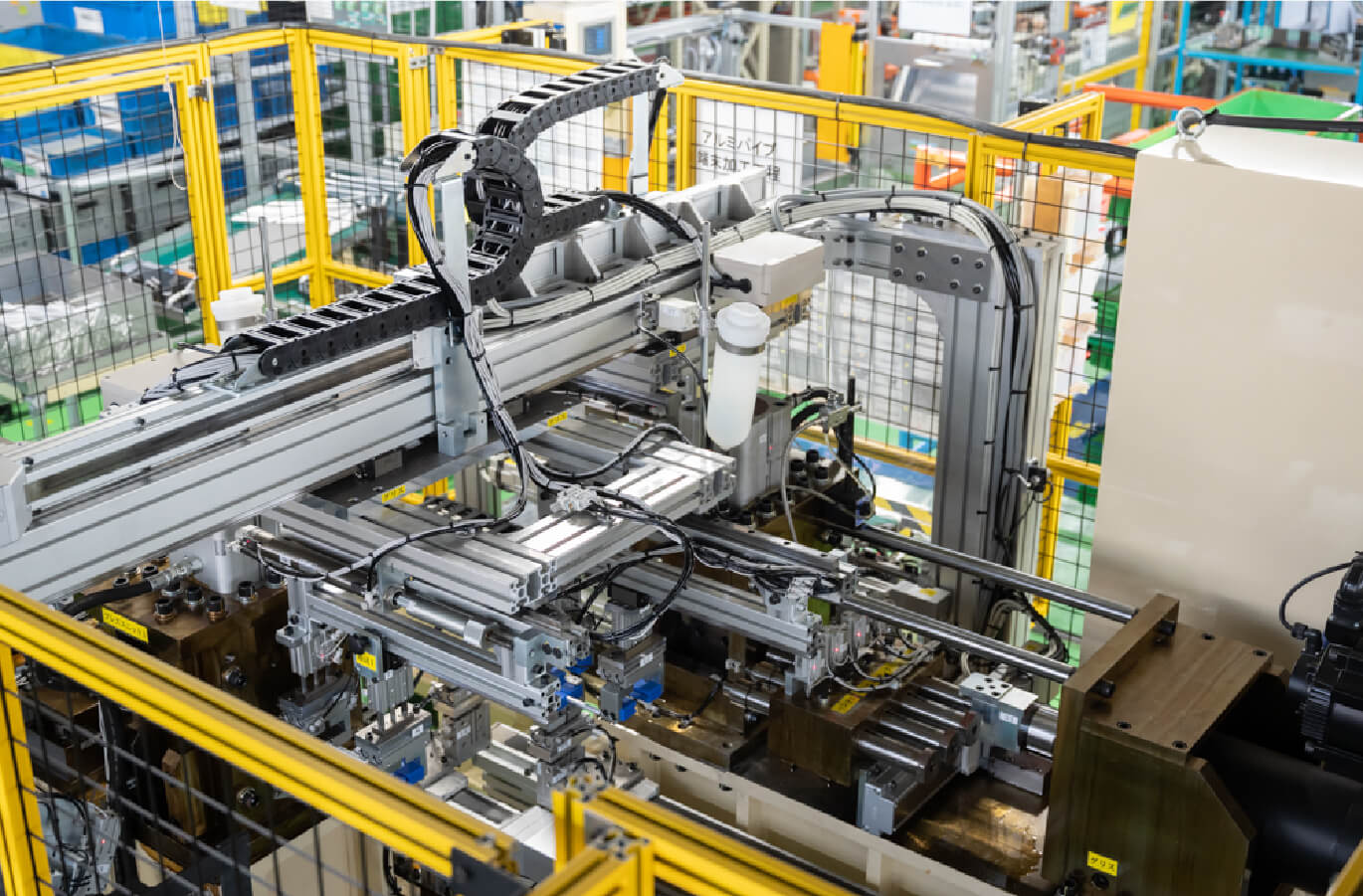

Bending process technology

Technology to bend pipes into the required shape.

It supports various materials and dimensions.

Select the optimum process according to the production volume.

(Dedicated bending machine/general-purpose bending machine/double bending machine, etc.)

- Material -

Stainless steel/Iron/Aluminum/Resin

- Main products -

- ・Fuel pipe (Iron, Resin)

- ・Brake pipe (Iron)

- ・Cooling pipe (Stainless steel, Aluminum)

- ・Oil pipe (Iron)

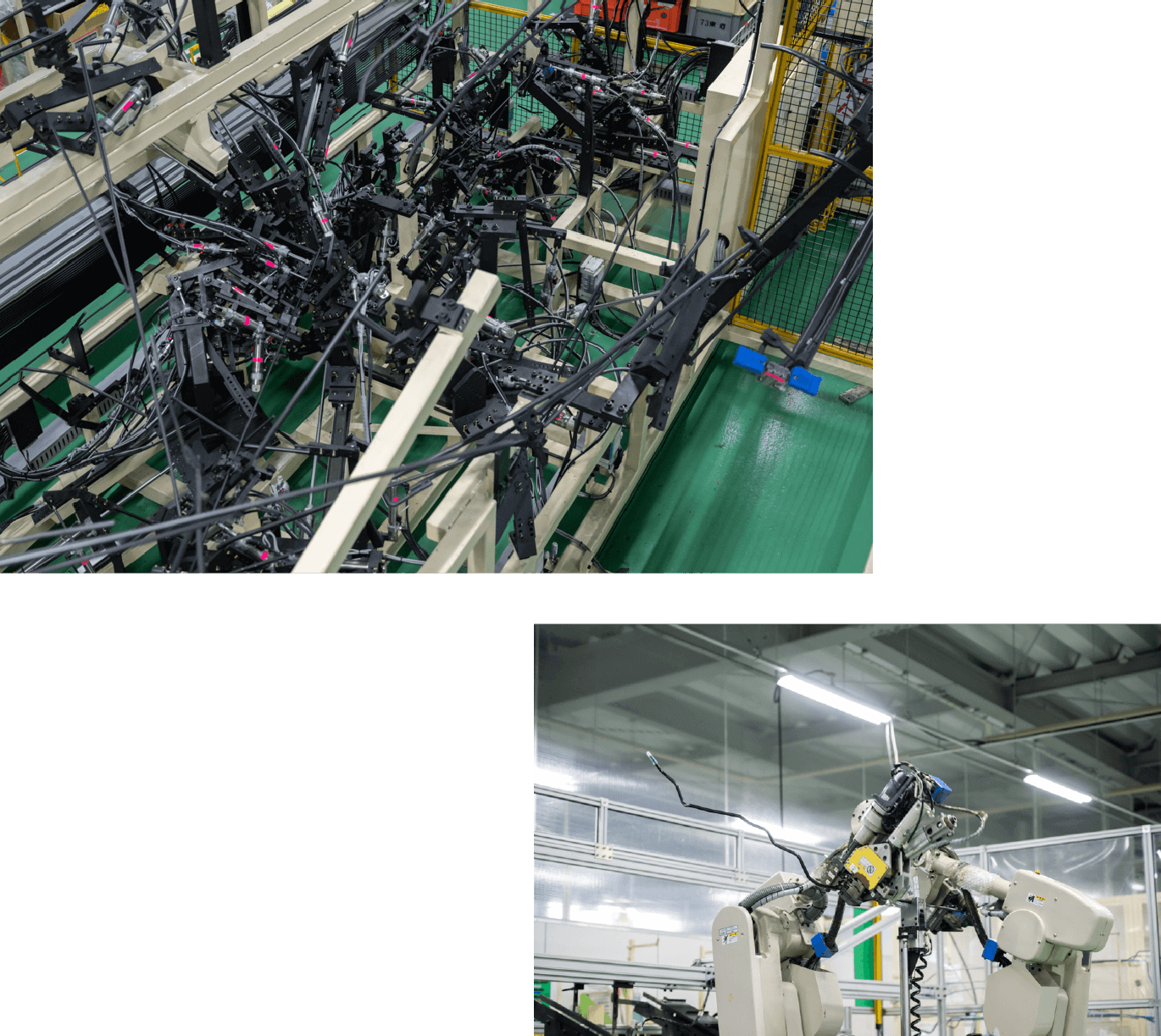

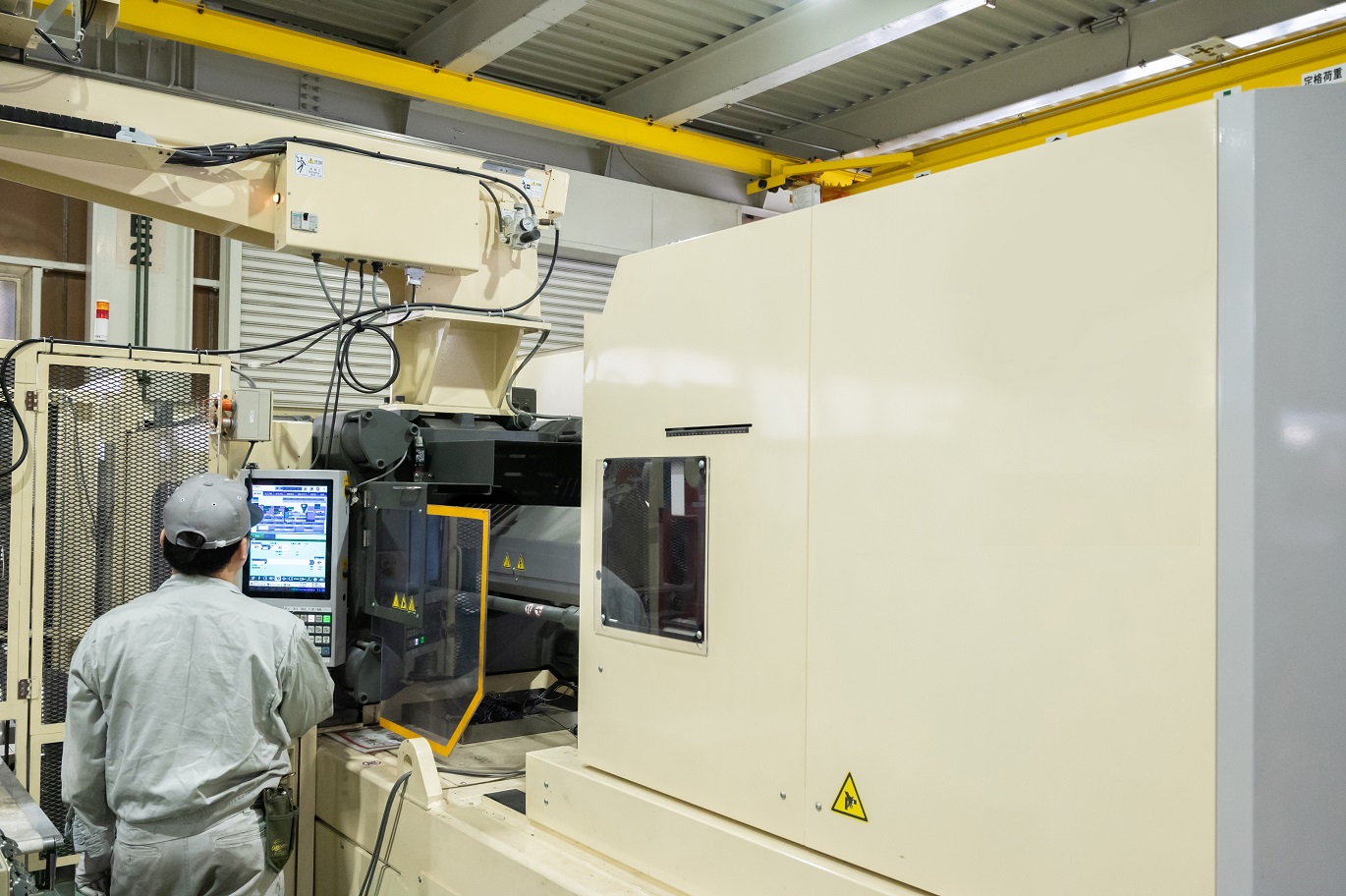

Resin injection molding technology

Technology to pour melted resin into a molding die and mold it.

In injection molding, it is also possible to produce tubular products with PIT molding.

* PIT:(Projectile Injection Technology)

It is one of the injection molding technologies.

After injecting resin into molding die, a bullet set in the molding die in advance is shot by high pressure gas and push the solid part out in order to make the product hollow (into a pipe shape).

- Material -

Poly phenylene sulfide (PPS)/ Polyamide

- Main products -

- ・Resin water pipe

Resin extrusion technology

Technology to push heat-melted resin through a molding die and form it into a cylindrical shape. It can mold various materials by adjusting the mold temperature.

By changing the mold size, it corresponds to range of outer diameter from 4.8mm to 21 mm.

It is also possible to change the wall thickness.

- Material -

Polyamide/Other thermoplastic resin

- Main products -

- ・Resin purge pipe

- ・Air suspension tube