Maruyasu Quality Policy

We assure safe and secure “Maruyasu Quality”

to our customers all over the world.

- We provide Good Quality products and services by following to established rules.

- We develop human resources through an education system that enables all employees to thrive in the workplace.

- We will work to resolve issues through Genchi-genbutsu (Go and see) checks and teamwork.

- We will actively promote communication throughout the Group

and build a system that prevents the same problems from recurring. - We will comply with customer requirements, laws, regulations.

- We set Quality targets every year and work towards achieving them.

- We will continually promote improvement to ensure the effectiveness of our quality management system.

Utilization of visualization technology

Activities to identify the root cause of problems

and make good products.

We use it to pursue better manufacturing methods by understanding what kind of changes are occurring

by processes and to identify the root cause when a problem occurs.

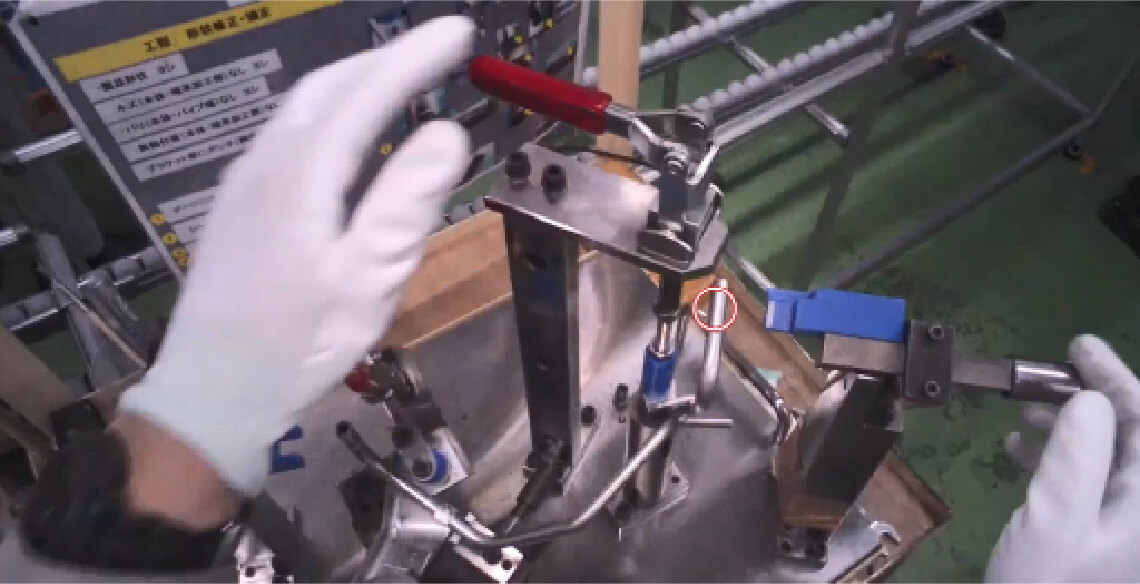

Utilization of eye camera

Creating a system that enable anyone to

make good things.

We have created a video manual using images taken with an eye camera so that anyone can understand the inspection process without omission.

In addition, we use an eye camera to analyze the movements and viewpoints of workers.

It helps us to check and improve workers’ understanding level.

Utilization of virtual images

Design a manufacturing line that can build quality

from the conceptual stage

We set up facilities virtually and designing optimal processes.

From the conception stage, we are thinking about how to reduce difficult work and make good products more efficiently.

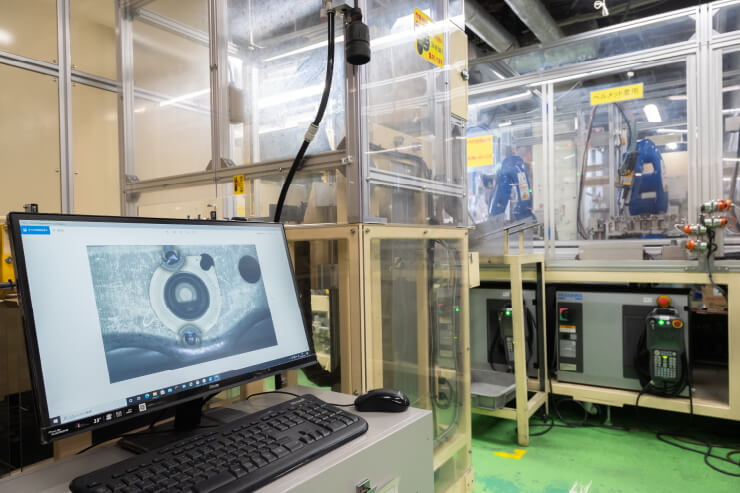

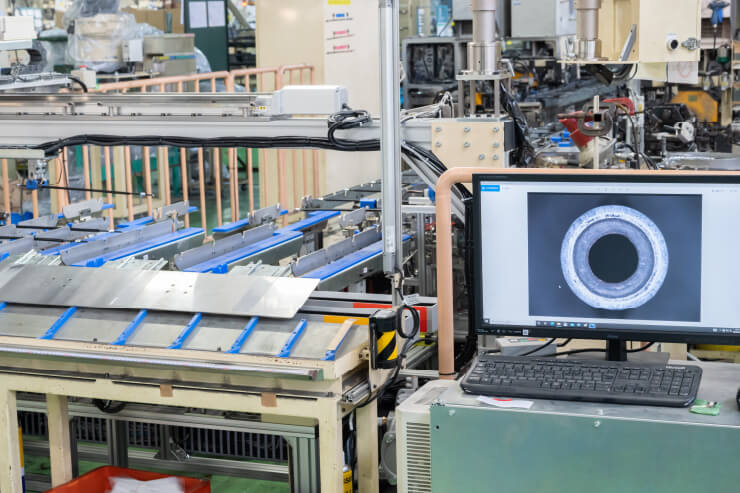

Utilization of AI technology for product inspection

A system that assures good things with confidence.

By eliminating variations in inspections by workers,

we supply products with appropriate quality to post-processes.

Checking portion of Tig welding

Checking tube ends

Developing human resources to maintain Maruyasu quality

Maruyasu Foreman Training

Training program aiming at developing human resources who will become leader in the future.

Trainees stay away from own workplaces and concentrate on improvement activities.

Thus, they acquire the ability to identify, analyze, and solve problems on their own.

Improvement activities at manufacturing sites

Study to confirm conditions to make good product

3M Circle

Improvement activity team by each workplace

Aiming to create a fun and active workplace that respects humanity, we carry out persistent small group improvement activities that make the most of our company’s characteristics (harmony among people).

Active participation in presentations outside the company

Walkrally hold as a part of strengthening teamwork

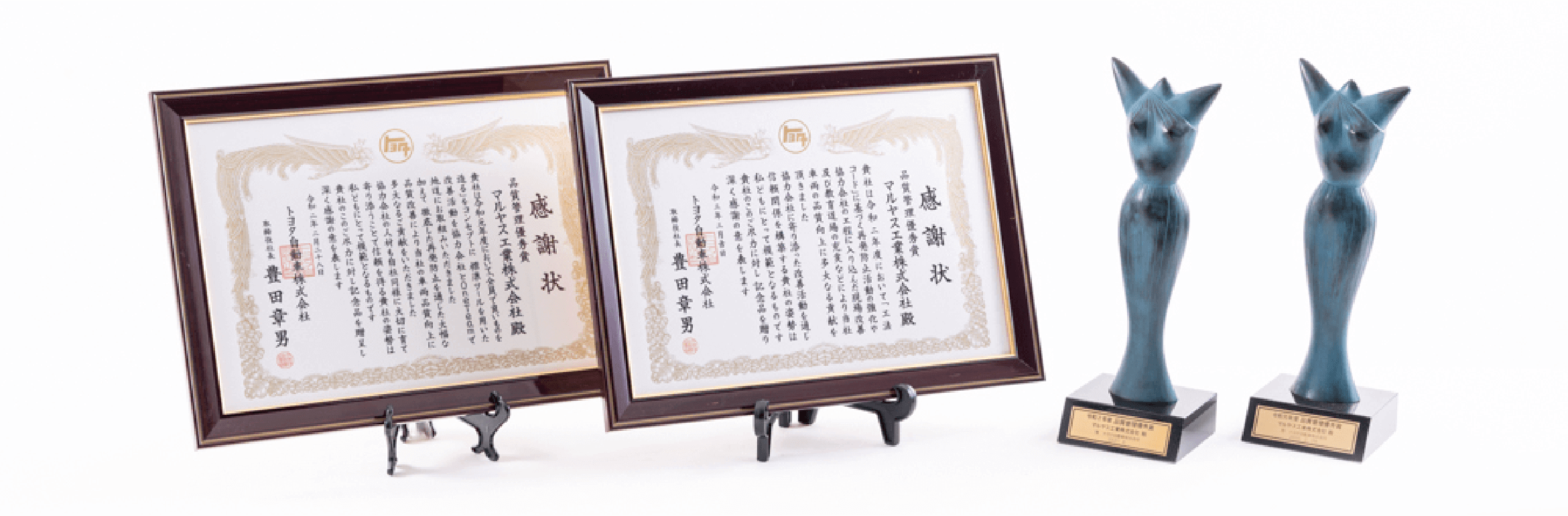

Award for quality

We continue to provide quality that

satisfies our customers.