Technologies to investigate or analyze metal materials, organic materials and

products, such as surface analysis, element/physical property analysis,

spectroscopic/separation analysis, and non-destructive internal observation.

By conducting material development, foreign substance investigation,

product non-destructive inspection, etc. in-house, we have realized shortening

development period and problem-solving period.

FE-EPMA

Method to investigate the composition of the sample by irradiating the sample surface with an electron beam and analyzing the generated characteristic X-rays with a wavelength dispersive X-ray spectrometer (WDS).

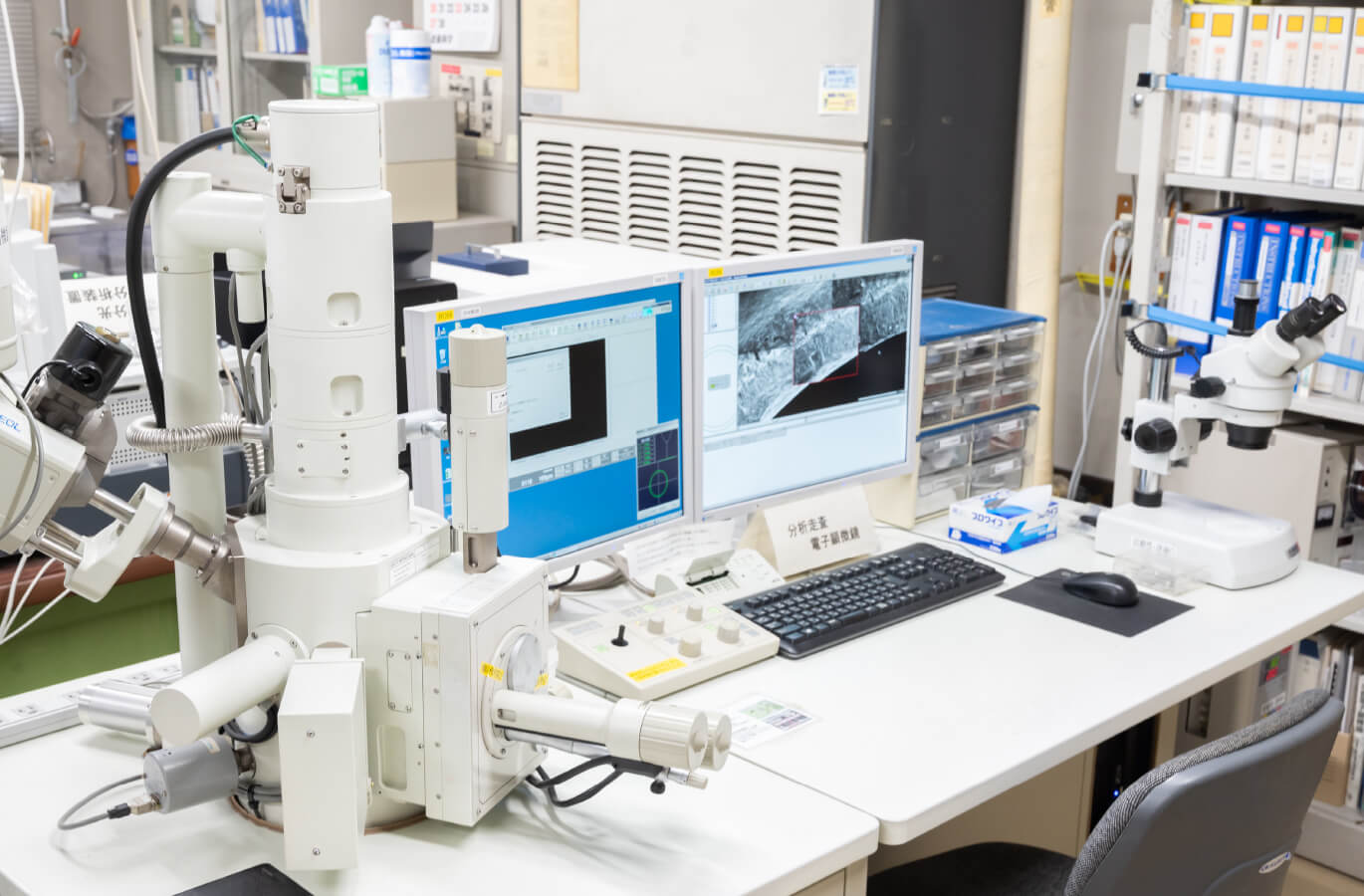

SEM-EDS

Magnify and observe surface condition with the intensity of secondary electrons and reflected electrons generated by irradiating the sample surface with an electron beam.

Energy dispersive X-ray spectrometer (EDS) is also equipped. It acquires elemental information by detecting characteristic X-rays generated during electron beam irradiation.

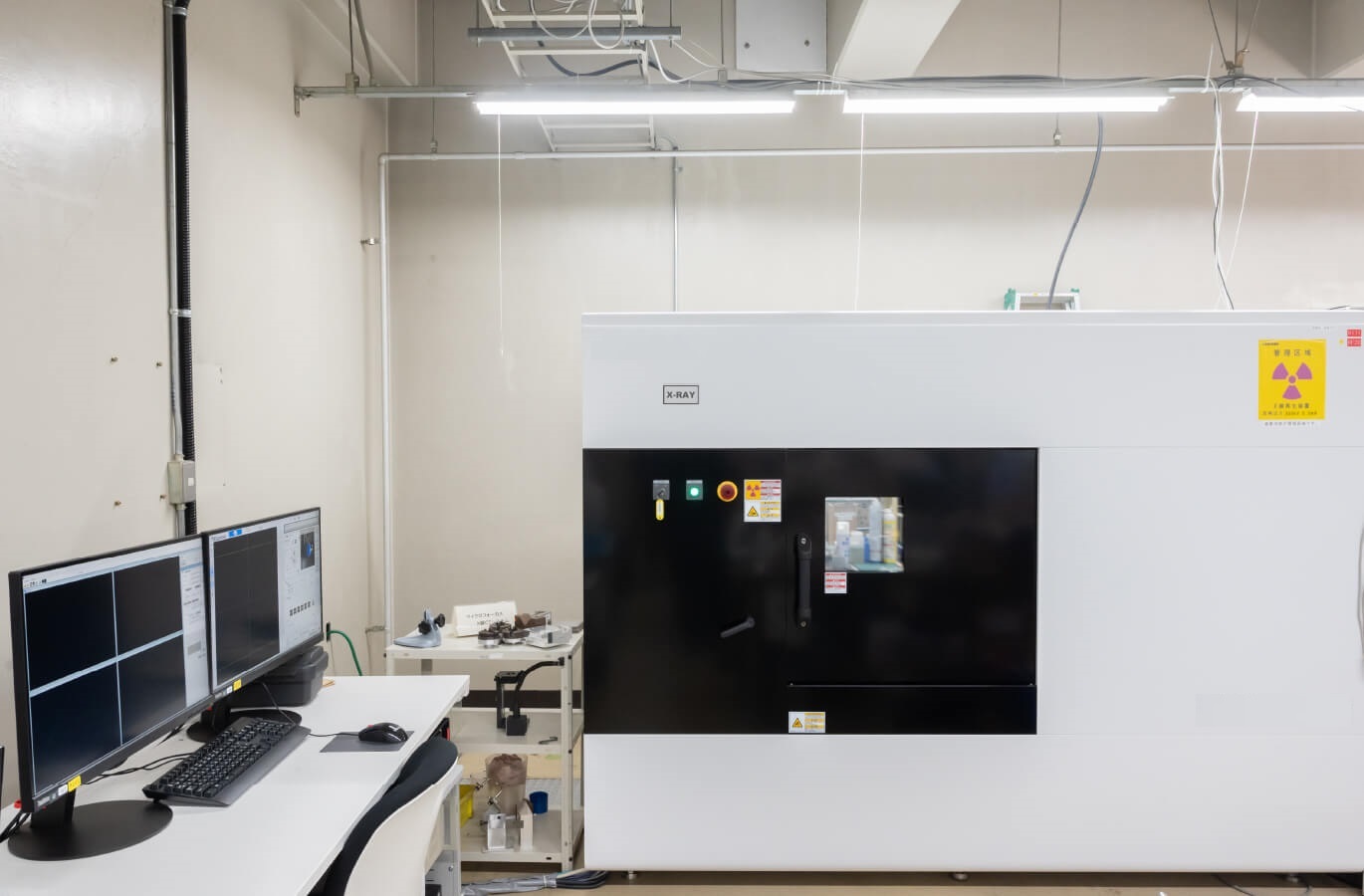

X-ray CT scanner

Observe the internal structure of an object by irradiating it with X-ray and detecting difference in amount of X-ray that is different by material or structure.

Three-dimensional information can also be acquired by computer processing data observed from 360-degree directions.

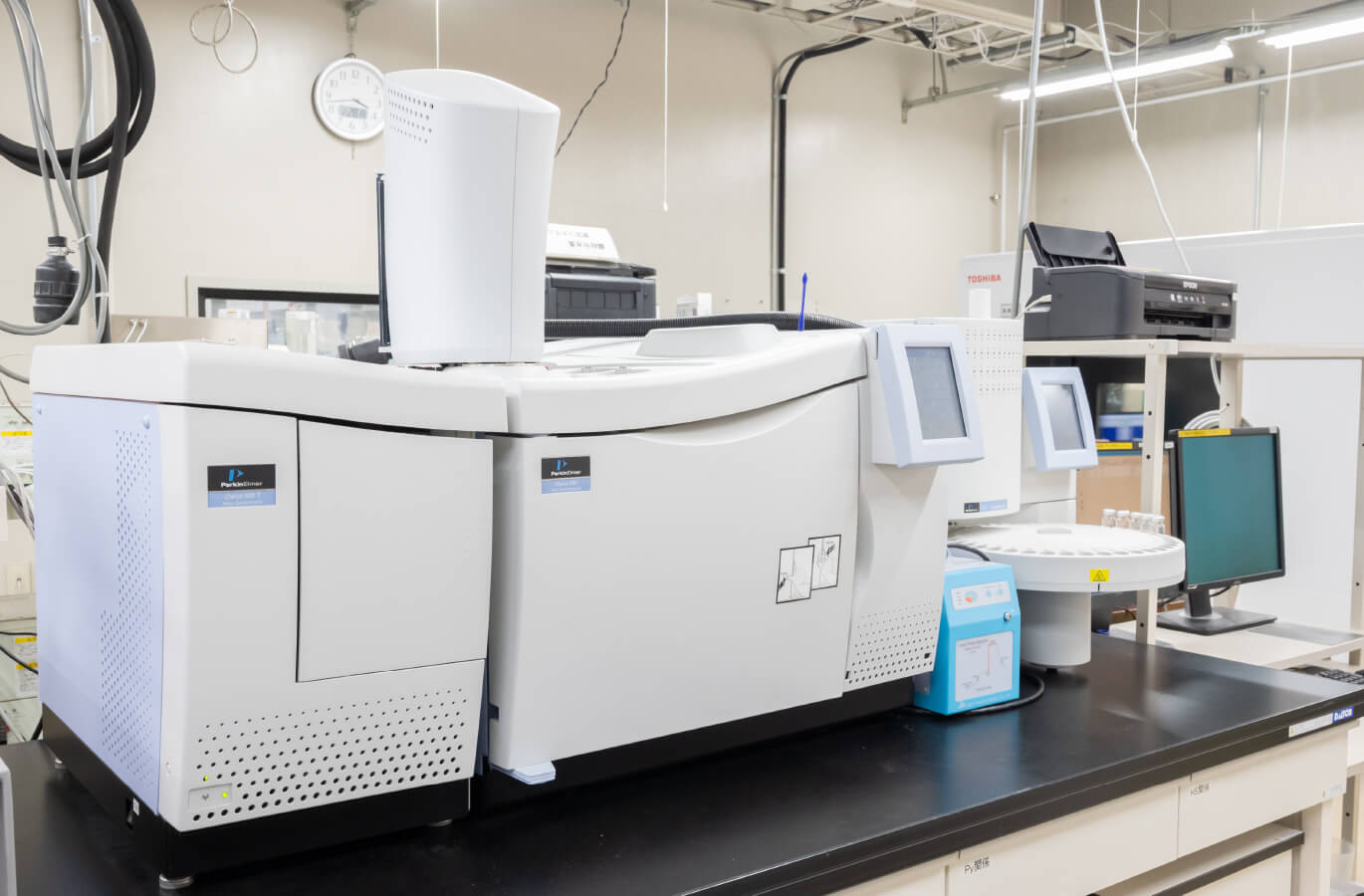

Gas chromatograph

Mass spectrometer

(GC/MS)

The sample components are vaporized in the pretreatment device and separated by GC into each component (compound).

Detecting the separated components with a mass spectrometer and make qualitative and quantitative analysis.

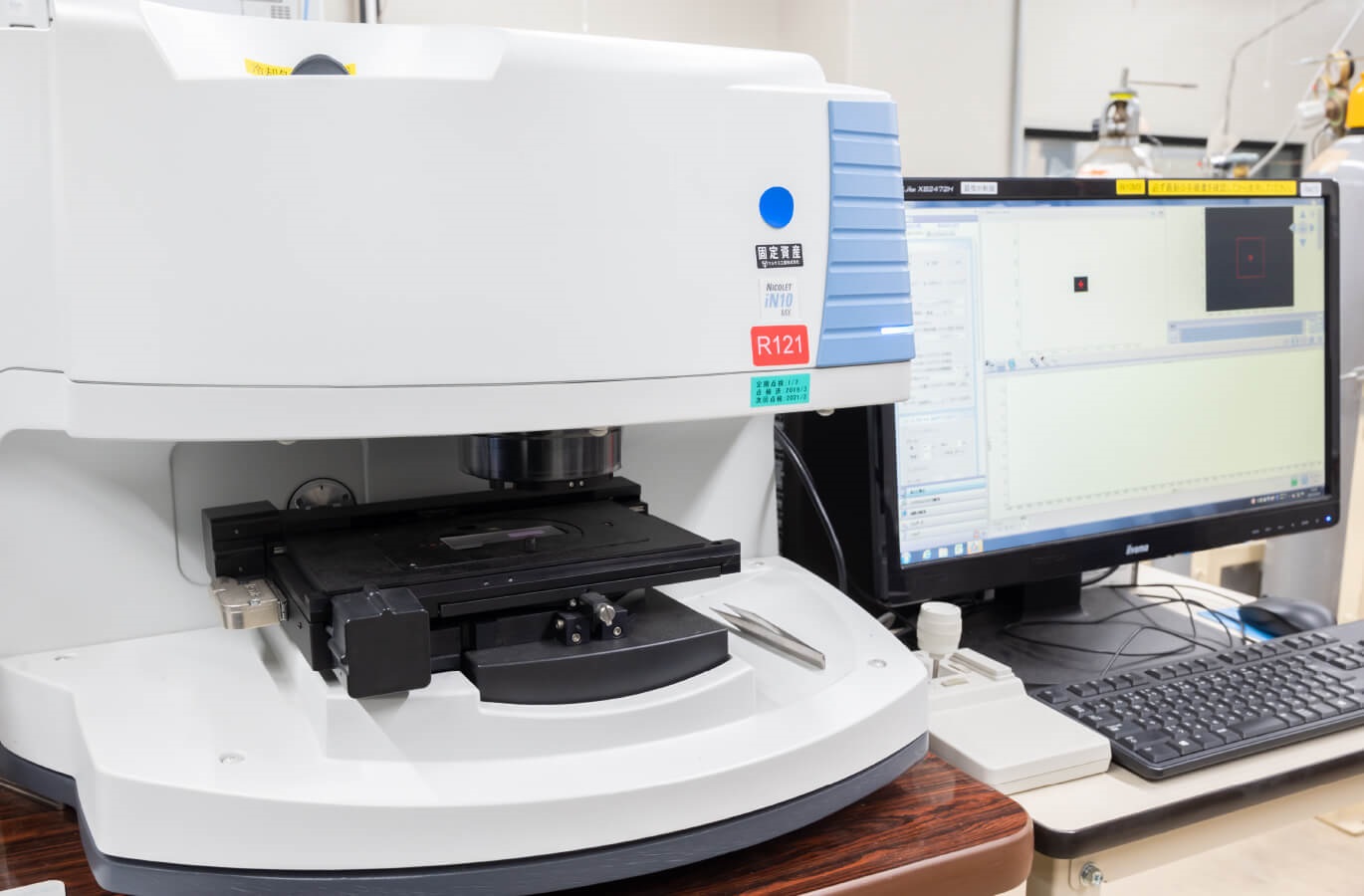

FT-IR

Microscopic FT-IR

Making qualitative and quantitative analysis using the IR spectrum obtained by irradiating the sample with infrared light.

FT-IR microscopy enables analysis of micro-area that is too small to be seen.

Contaminant measuring device

Detecting micron-order foreign matter collected from inside of products, and discriminates the size, quantity, and type (metal, carbon, fiber) by using high-speed image processing technology.